Hex Meshing

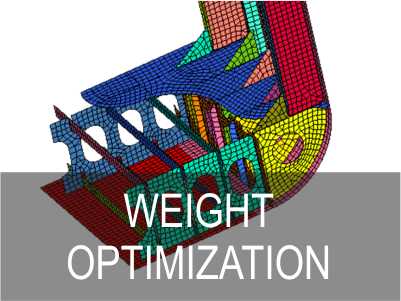

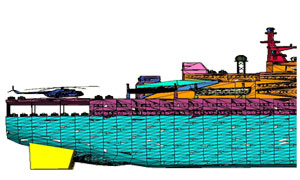

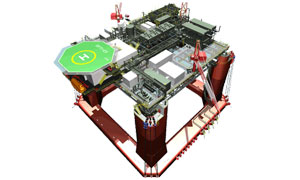

Hex Meshing is a standard but complex collection of cubes, commonly used by DEP (Detroit Engineered Products) in variety of meshing techniques, which works as a part of geometry. It is mainly dependent on the computational designs of various shapes. Hex Meshing has zonal boundaries and the internal and external zonal boundaries are free to make use of different zone shapes. Hex Meshing also allows Concept design options, which can help in analyzing geographical and cartographic data.

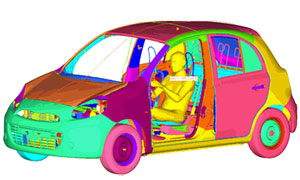

DEP (Detroit Engineered Products) offers various techniques of Concept design which help in deciding the type of mesh, which is based on computational efficiency and the accuracy. The meshes are used in various designs, styles and shapes are most common type of engineering designs highly popular across India and USA.

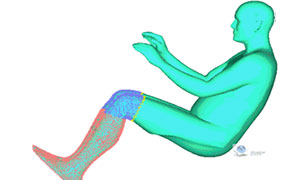

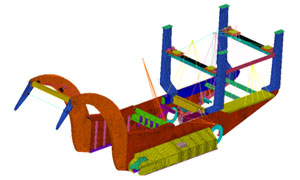

Hex Meshing is highly important part of system simulations, which can change drastically from the basic design to the advanced level. Meshing is process which starts with grid-points which are called as nodes. Every point in the mesh represents an area, which needs to be connected to the points on the other sides. Hex Meshing is mainly based on various forms of Concept design, which are either well-structured or created in a systematic designs having a particular shape. Hex mesh offers a calculated design, which is mainly based on calculated governing equations, which are relevant to the each of the node of the mesh. Meshing can be done with the help of variety of techniques and technologies. Hex Meshing offers highly advanced tools for designing and creating the meshes, which are used in the mechanical engineering industries around India and USA.

Make use of limited computerized resources and restricted to use computer and the disk space offering-by-offering highest accuracy while designing the tetrahedron mesh.

Hex meshing can be created using controlled mesh metrics, which can easily comprehend entire mesh geometry completely.

- The general Rule of Thumb for Hex Meshing

- Hex mesh should be used with clean topology

- Hex mesh should make use of sweep meshing

- Make use of split bodies or slices for more control

- Fulfill the topological requirements using map meshable sides