Model Checker

MeshWorks model checker is a high level automated tool to validate CAE models. It has the automatic checking and fixing tools, which help easily and quickly remedy problems in CAE models.

The following can be checked in the MeshWorks model checker:

- Element quality check

- Washer identification check

- RBE3 weight factor check

- RBE3 DOF check

- RBE2 DOF check

- Material assign check

- Material value check

- Contact pair check

- Contact area check

- Contact penetration check

- Bolt pretention check

- Bolt diameter check

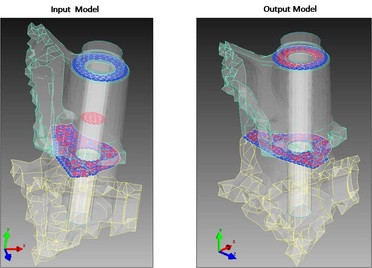

Contact pair check

This check specifically detects , whether the surfaces pairs are defined properly in the contact. While defining the contact , in some situation user may mistakenly selected the slave surface in one region and master surface is some other location of the model. This issue identified and fix automatically.

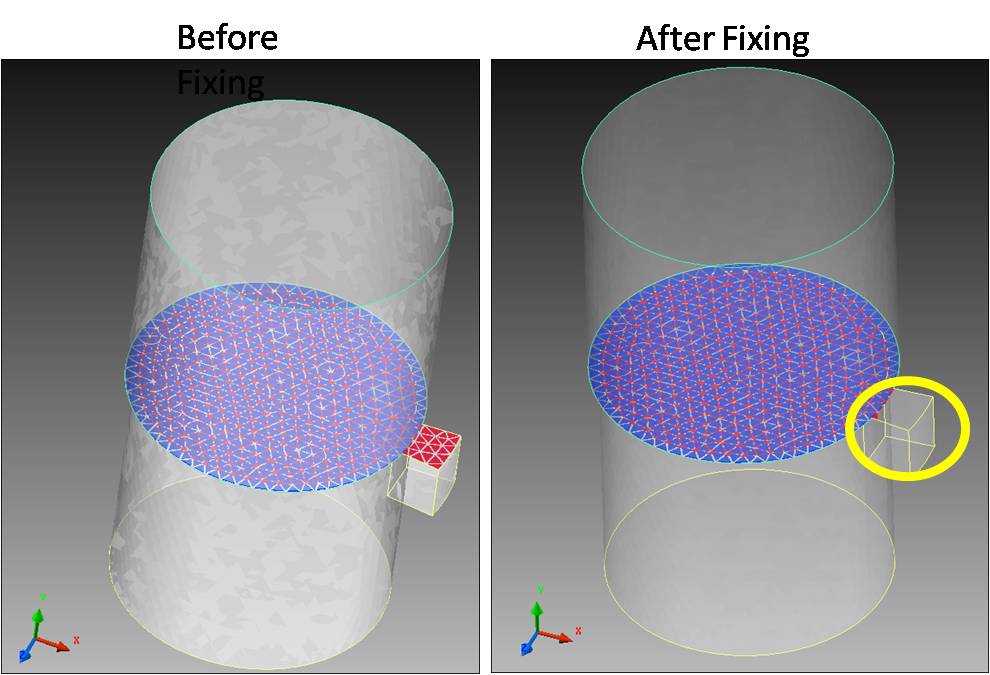

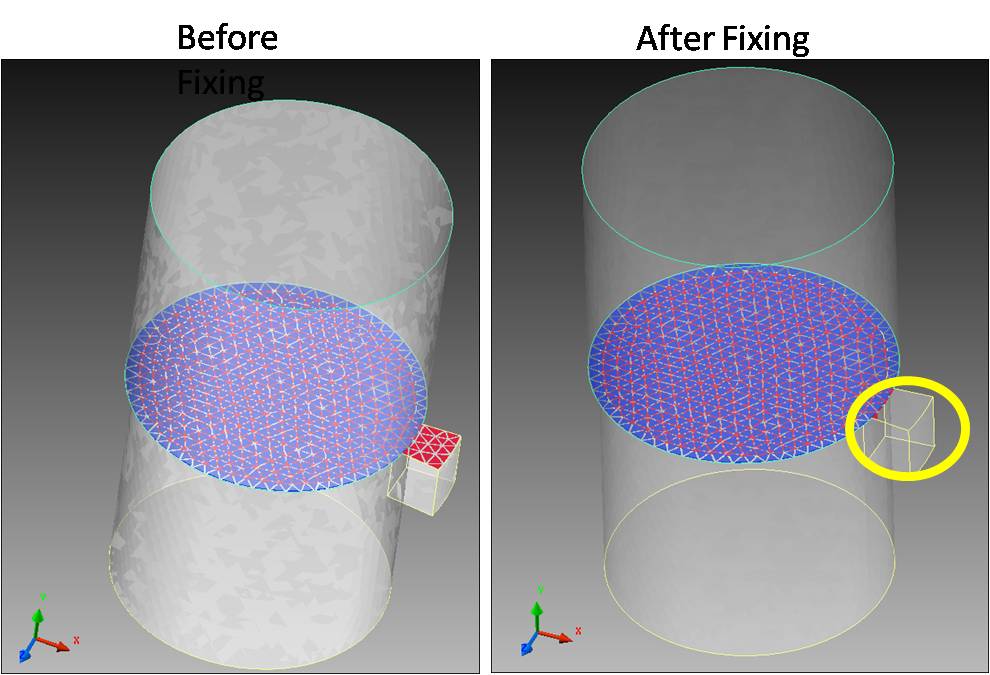

Contact Penetration & Gap Check

This check specifically detects the penetration & gap between the slave/master surface nodes in the contact pairs. This issue is identified and fixed automatically.

Contact area check

This check specifically detects whether slave surface area boundary is less than or equal to master surface area boundary . In some regions slave surface nodes will be away from the master surface nodes. This is issues will be detected using this check . Issue can be automatically fixed by updating the slave surface.

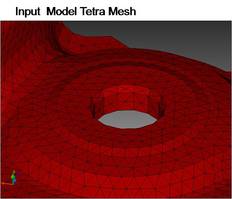

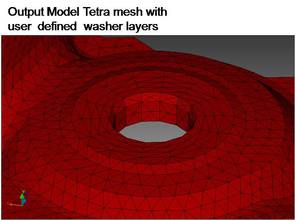

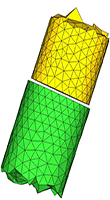

Washer identification check

This check is specifically detects the washer definition of the Tetra meshed parts in bolt holes