DEP MeshWorks is an integrated CAE platform for pre and post processing, involving rapid concept CAE and CAD model generation, parameterization and optimization, advanced meshing, process automation, concept modeling and CAD morphing.

DEP MeshWorks, from Detroit Engineered Products (DEP) is a CAE driven integrated platform for pre and post processing, involving rapid concept CAE and CAD model generation, parameterization and optimization, advanced meshing, process automation, concept modeling and CAD morphing. It has enabled leading companies across the globe to transform the product development cycle, thus considerably saving them time and money, and get to market faster. Since its release in 2001, DEP MeshWorks has been simplifying tedious time consuming processes associated with design changes, and helping reduce the product development cycle across several industries globally.

The latest major release of MeshWorks features new modules like a powerful FE/CFD pre & post processor, a customizable engineering process automation environment and has substantial depth and robustness added to its existing modules, all in an easy to use graphical interface.

Key benefits for customers using MeshWorks

Comprehensive FE/CFD pre & post processor with powerful tools for CAD clean-up, meshing, highly automated model assembly and results processing

Highly automated meshing and model assembly tools reduce CAE model building time by by 40 to 50%

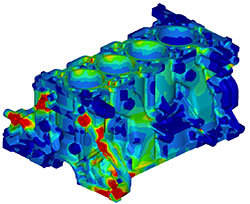

Automated post-processing such as ‘hot-spot-extraction’ reduces several hours of post-processing time to a matter of minutes

Very effective design review is now possible with MW2020 with all the hot-spots unionized in one single model and facilitates subsequent design improvements to make ‘hot-spots’ go away

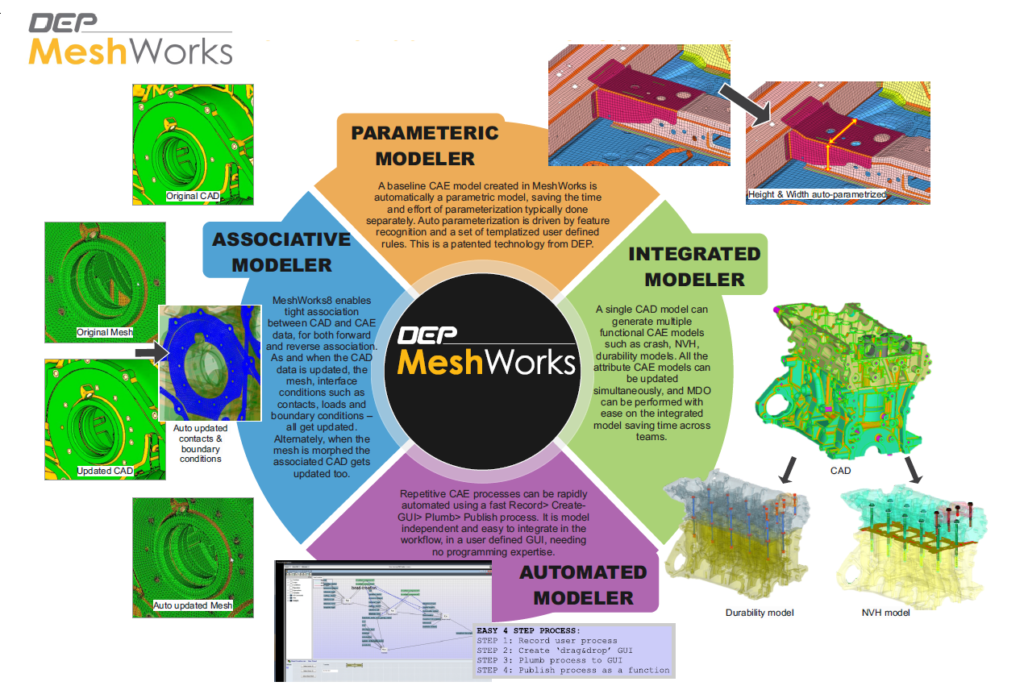

With the patented Auto-parametrization technology the meshed models in MW2020 automatically become parametric CAE models enabling subsequent fast design changes

The Associative Modeler in MW2020 rapidly updates CAE models as CAD changes, dramatically reducing time for model updates

Likewise, as CAE models are modified by the engineer to improve performance and reduce weight, the CAD models are also automatically updated

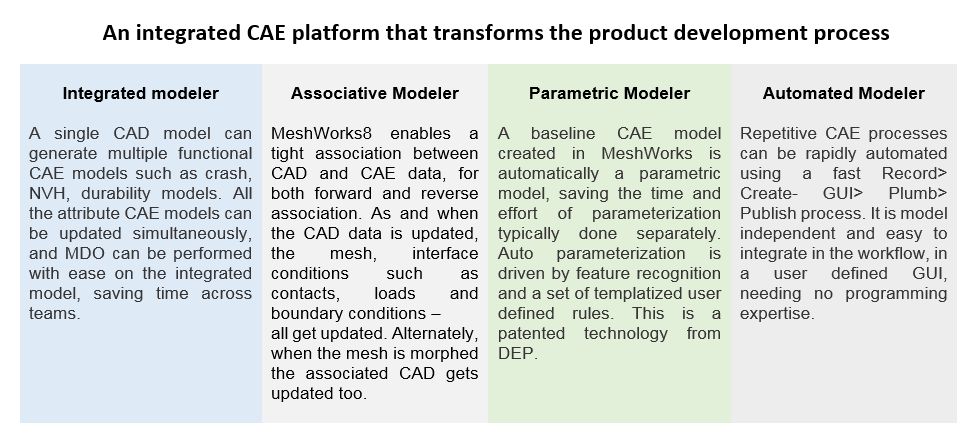

The Integrated Modeler in MW2020 generates multiple attribute models (Crash, NVH, Durability, CFD etc.) from one single data base eliminating parallel efforts required to create multiple models

Customer CAE processes can be rapidly automated resulting in 2x to 10x time reduction using MW2020’s highly graphical Process Automation Environment with zero scripting skills needed

CAE Morphing has been taken to new heights with the automated control block creation technology (global & local) reducing time and skill required for morphing dramatically

The CAE concept modeling module forms a perfect complement to the morphing module allowing very rapid creation of FE/CFD members, joints, features etc. at the click of a button

Existing FE & CFD models can be converted to intelligent parametric CAE models, enabling fast design iterations & Design Of Experiment(DOE) studies

MW2020 enables Multi-Disciplinary Optimization to meet design targets, minimize product weight and manufacturing cost using parametric CAE models

MW2020 is a perfect pre-processor for topology optimization and Additive Manufacturing (AM) enabling lattice based topology optimization by automating a) defeaturing & creation of a minimalist design model, b) creation of the design space automatically and c) creation of concept FE models in a highly automated fashion

MW2020 can generate very high quality CAD models using the patented CAD Morphing technology to exactly represent the optimized CAE models – thus forming a perfect hand shake to the design department

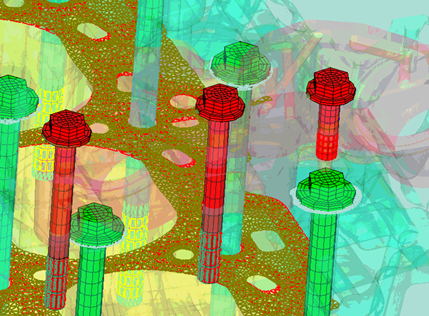

MESHING

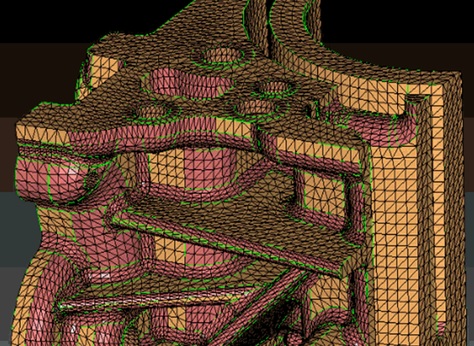

MeshWorks has a powerful CAE meshing engine that allows users to create 2D and 3D meshes rapidly from complex CAD data. Highly automated meshing functions available allow users to create exceptional quality meshes with minimal user intervention in the shortest time possible, with minimal to virtually no CAD clean-up.

Read More >>

MODELING

The Modeling module within MeshWorks comprises of a set of interactive and highly automated model assembly, model connection, materials, loads and boundary condition assignment functions that will allow users to create complex full system level models such as that of automotive vehicles, IC engines, airplanes, ships etc. in a highly condensed time frame.

Read More >>

POST PROCESSING

MeshWorks is a multi-disciplinary post-processor for viewing and publishing the results of analysis. It allows for loading and viewing the result files obtained from various solvers.

Read More >>

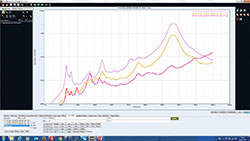

GRAPHING

MeshWorks graph is a powerful plotting and data analysis tool. It has a rich set of plotting features, a user friendly interface, easy navigation from function to function, and is fully integrated within the MeshWorks interface.

Read More >>

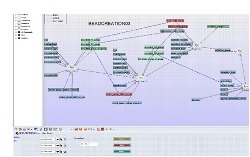

PROCESS AUTOMATION

Customer CAE processes can be rapidly automated using a fast Record > Create-GUI > Plumb > Publish process. Very complicated geometry and mesh creation processes can be automated with virtually no scripting or programming expertise.

Read More >>

CAE MORPHING

DEP MeshWorks is a feature based morphing tool that can rapidly morph existing FE and CFD models to match new geometry and/or to new proportions. Component and full system level FE/CFD models (such as automotive vehicle crash, NVH and durability models) can be morphed to fit target design features such as styling lines, sections, proportions etc. precisely.

Read More >>

CONCEPT MODELING

MeshWorks has advanced cutting, blending and stitching functions to create early stage concept FE and CFD models very rapidly.Local regions from the donor FE or CFD model can be cut, morphed and stitched to the target FE/CFD model resulting in a new concept quickly.

Read More >>

PARAMETRIC MODELING

MeshWorks is a comprehensive CAE model parameterization engine with a broad range of categories of parameters that can be used at all stages of product development.Regular FE/CFD models can be converted to intelligent parametric FE/CFD models. The parameters can be exercised as one-time execution or linked to DOE and MDO schemes.

Read More >>

DESIGN ENABLERS

MeshWorks has a powerful Design Enablers which enables rapid creation of finite element features such as ribs, holes, slots, reinforcements, bulk-heads, beads, darts, part-extensions/contractions, laser welded blanks etc. directly on FE/CFD models without the need for CAD.

Read More >>

MDO

DEP MeshWorks based parametric & non-parametric CAE models facilitate Multi-Disciplinary Optimization to meet design targets, minimize product weight and minimize manufacturing costs MeshWorks parametric models can robustly generate multiple runnable analysis data sets given a DOE matrix.

Read More >>

CAD MORPHING

The CAD morphing module allows users to morph existing CAD data (body structures, powertrain and chassis parts) directly to new shapes rapidly. It enerates morphed CAD models representing optimized designs very rapidly and forms the main link between CAE & Design teams, saving several months of CAD development.

Read More >>

Solver interface and supporting platforms

Supporting Platforms:

- Windows 64 bit (7,8,10)

- Windows Servers

- Red Hat and SUSE Enterprise Linux 64 bit (Workstation & HPC)

CAD Interfaces:

- Parasolid (text & binary)

- STEP

- IGES

- CATIA V4 & V5

- JT

- UG/ NX

FE Interfaces:

- STL (ASCII & Binary)

- MSC Nastran

- Abaqus FEA

- ANSYS

- LS-DYNA

- Pam-Crash

- RADIOSS

- Fluent

- SC/Tetra

- STAR-CD

- MADYMO

- OptiStruct

- GENESIS

- CONVERGE