Post processing

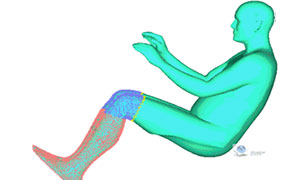

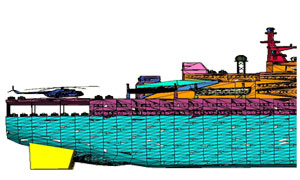

Project processing is a visualization process, which monitors the on-going processes and allows a complete post-processing plan to take care of the entire processes. In the industrial environment, DEP (Detroit Engineered Products) makes it necessary to keep the track of the processes, understanding the required changes and also study information available to offer better solutions to the problems at hand.

Design for manufacturability offers various visualization, interrogation and comparison techniques which could help in supervising the processes at the post processing level and to offer better solutions to improve the entire processes completely, in case needed to bring certain changes and is highly preferred in the business conducted in India and USA.

Post processing offer highly useful techniques of Design for manufacturability and makes it effective while controlling the entire processing phase. It is a phase which keeps displaying various outcomes which are fascinating and keeps the environment charged with complete interest and excitement. The post processing stage is not for doing any experiments but to supervise the work and to understand the working process which either shows flaws at various levels or it could help the organization to achieve the targets and to fulfill the goals set. The post processing stage is most commonly used by DEP (Detroit Engineered Products) and it makes it easy for the India and USA management departments to visualize and to monitor the outcome and to study the related factors which brings clarity in the working of the organization.

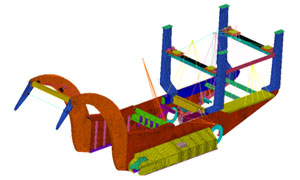

The various factors involved in the post processing stage and supported by DEP (Detroit Engineered Products) are:

- Getting the various processes streamlined which works effectively

- Offering multi model support which is very essential

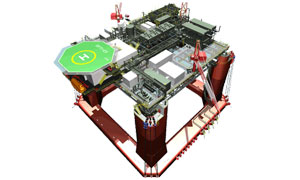

- Set new standards to get effective results

- Integrating different techniques and technologies to offer better working techniques

- Monitoring the interaction closely between different technologies

Design for manufacturability is a technique capable of offering better results after the post processing phase but it also displays the better results which surely helps in facing the up-coming industrial challenges. The post processing is always the most exciting stage and it always bring more surprises at the later part in the business offering unexpected end results.