On-demand Webinar:

Warpage correction and part distortion reduction in injection-molded designs using MeshWorks2020

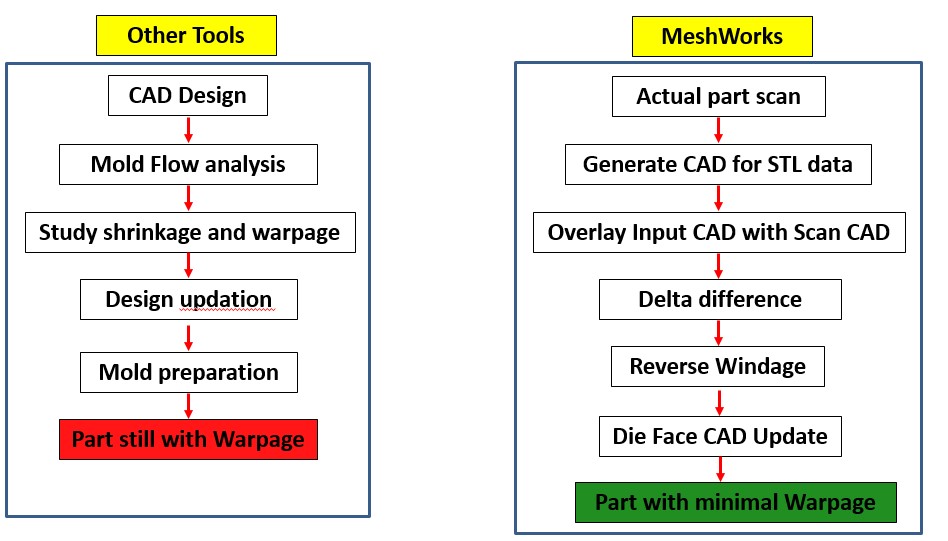

Plastic parts warpage compensation and part distortions stress reductions were some of the major challenges for the manufacturer. With the latest in MeshWorks2020, there are an impressive set of tools which work together with your existing tools and processes to reduce the manufacturing defects correction time drastically. With DEP MeshWorks, you get a single integrated pre-post processor, essentially eliminating the need of shuffling across multiple software, which can save you up to 80% of your time.

This webinar focuses on a pain point for many plastics part manufacturing and will cover how MeshWorks can help you save time and effort.

Topics that will be covered in this webinar:

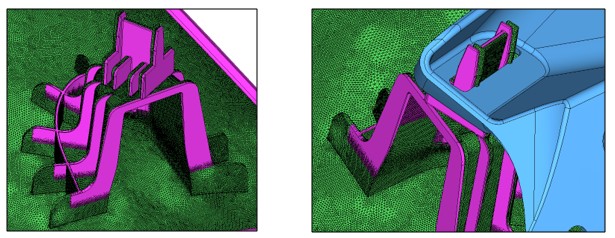

- Automatic die face correction for warpage– Learn how the CAD Morphing technology in MeshWorks can automatically update the tooling CAD to compensate for part warpage as predicted by simulation from software like Moldflow or with the warped geometry from the scanned part.

- Deficiency due to part distortion inducing forced assembly process.

- Glues will be stressed due to pre-stresses in the plastic and leads to performance deterioration.

- Bolt connections, locators, dog houses or clip locations may get overloaded when clamped.

- Lack of methods to study the de-bonding effect from the assembly process.

Meshworks2020 has the quicker solution to overcome warpage in injection molded parts!!!

Meshworks2020 process is 80% faster!!!