UPCOMING WEBINAR

Reverse Engineering, Scanning, Benchmarking, and CAE/FEA/CFD Simulation – Innovative Technologies and Product Development Best Practices from DEP

US Session – Dec 9

EDT: 2:00 PMPDT: 11:00 AM

Duration: 45 minutes, followed by live Q&A

Who Should Attend?

- Product Design and Development Team

- Reverse Engineering Team

- Benchmarking Support Team

- Simulation Managers and Analysts

- And teams who are part of product development cost reduction programs

This webinar will be extremely useful to you & those working in Automotive, Aerospace, Power Generation, Medical, Defense, Consumer Products, Marine, etc.

About the Webinar

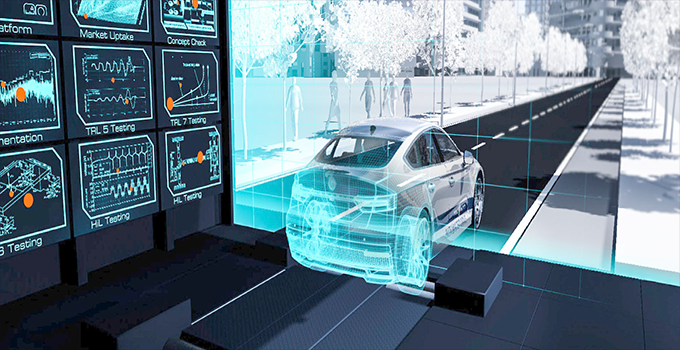

DEP would like to invite you to join our webinar for a quick overview of our engineering solutions and automated processes to reduce component/product cost, reduce Design & Development time, and better optimize products for safety, weight, durability, cost and efficiency. We offer award winning project delivery thanks to our in-house Engineering CAD/CAE expertise and our patented MeshWorks Engineering Software platform including powerful CAE Meshing, CAD/CAE Morphing, and Automated Lightweighting capabilities.

In this webinar we will be showcasing:

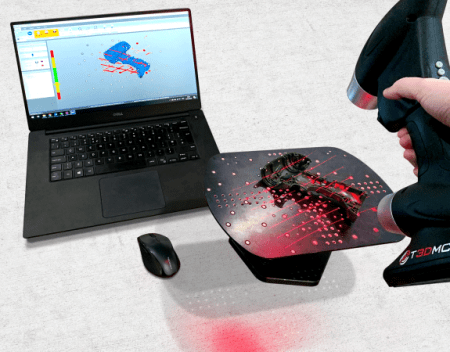

Reverse Engineering processes and best practices for scanning and 3D model creation

Rapid Concept Development based on topology optimization results or benchmarking process with zero CAD to save time for CAE Engineers

Innovative Morphing techniques to quickly redesign the product for new requirements to save time and efforts as compared to traditional approach of “start from scratch “

Lightweighting & Optimization techniques using DOE including use of patented specialized tools like “MeshWorks”

-

Innovative CAD model regeneration techniques for the final optimized CAE model for a perfect handshake between CAE and design

-

Cost Reduction and Component Commonization

The value that DEP and MeshWorks brings to our clients includes: reduced costs through Lightweighting, material selection, manufacturability improvements, higher levels of optimization for product safety and durability, and a reduction in man-hours to complete Design and FEA/CAE/CFD simulation efforts saving our clients time and money.

DEP Reverse Engineering, Scanning, and Competitive Benchmarking Services

DEP offers a comprehensive benchmarking and teardown/assembly analysis for our clients. Key Offerings includes:

Teardown, Benchmarking and Digitizing – 3D Scanning / Industrial CT (X-Ray), Parametric 3D CAD model generation from scan data (our laser scanning is portable and we can travel)

CAE model generation from reverse engineered CAD – Finite Element models, CFD models, 1D system models (GT Power etc.)

Correlated CAE/CFD models as part of benchmarking process – Flow-Bench, Particle Image Velocimetry (PIV), and Dynamometer-Lab test to correlate models. Correlated FEA & CFD models, correlated 1D system models

Parametric CAE models as part of benchmarking process – Parametric FEA & CFD models of competitor parts can be used to create new designs rapidly

DEP Engineering Services

Our Engineering team utilizes all major CAD Systems (Catia, UG/NX, SolidWorks, Pro-E/Creo, AutoCAD Inventor, etc.) and major CAE platforms (ABAQUS, LS Dyna, ANSYS, MSC Nastran, Fluent, Star CCM+, GT Power, Adams, Moldflow, COMSOL, etc.)

DEP has a core Engineering Staff that can take ad hoc Design and FEA/CAE/CFD Analysis the SAME DAY you call. This is a great solution for not taking on a short-term employee and eliminates a lot of tedious paperwork and reporting.

We can host teams from 1 to 25 Engineers in our office complex (owned by DEP) and have 24 to 48 hour turnaround on most quotes once data packages are received. We can also offer hybrid pricing and cost reduction options by incorporating DEP offshore teams as well as providing on-site Project Engineers to support the outsourcing of work packages. Our teams can co-locate at your facilities.

DEP also conducts Employee AND Contractor Training Programs for: CAD Design, FEA/CAE, and Electronics (ADAS). To better support our Clients resource needs, DEP uses a system for on-line real-time updates for Recruiters and Staff for: Candidate selections, submissions, interviews, and the entire on-boarding process.

Some of the other key engineering service areas that DEP can support you includes the below.

DEP Staffing, Recruiting, Project Team Creation

Our “Staffing, Recruiting, and Project Team Group” is a one-stop source for our client’s personnel needs as well creating small to large teams for project support. We do Contract, Contract-to-Hire, and Direct Hire staffing. DEP has 10 Recruiters on Staff using 24-hour multi-shift Recruiting (Michigan, USA and India). We can recruit Engineers for domestic and global positions.

DEP Product Development

Detroit Engineered Products is also known for our Product Development capabilities in all industries including Medical Devices, Agriculture, Automotive, Aero Drones, and our soon to be commercialized “Engine Ion Sensor” for better fuel economy, reduced emissions, optimized Diesel Aftertreatment system capabilities and Multi-Fuel enablement.

DEP has been awarded multi-million dollar contracts for engineering services from the largest Suppliers, OEMs, and Defense Industry Primes in the world. We’ve also worked with one person innovators to help their product development dreams become a reality.

In this webinar, we will be speaking in-detail about all the latest engineering techniques implemented and the successes. For exclusive meetings, we are open to have quick chat to see how we can help fill the gaps and be a multi-purpose partner!

The event is free, but registration is appreciated.