What an Effective ‘Teardown’ at DEP Means

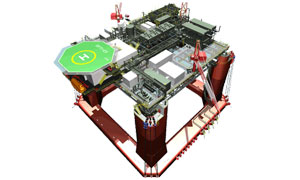

A smart way to gain insights and tweak the processes for improvement in the design of the torn down components that affect the total costs of procurement is to do a complete teardown of the products. Factors like materials used, procurement costs of individual components, specifications, competitive product analysis, product design etc are effective tools. DEP‘s process involves complete product disassembly for comparisons with competitive products to better understand the process of innovatively improving or re-engineering the value and quality aspects to effectively reduce product costs and performance.

Some crucial factors in the workflow process are the cost of ownership, technology and functional requirements, regulatory compliance, time to market, and such. Typically the teardown activities like vendor selection, requirements gathering, goal setting, the implementation process, and testing are crucial components in the complex lifecycle management of engineering products. Product Lifecycle Management is at the heart of plant product design, maintenance, and upgrades. PLM provides the environment for the design workflow process where FEA and CAD files are worked on to provide ultimate solutions for version control and engineering change requests.

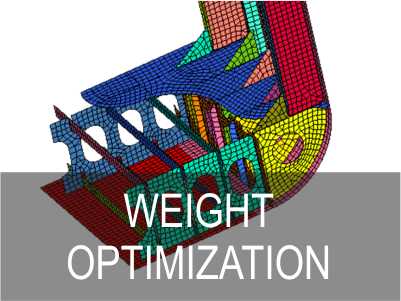

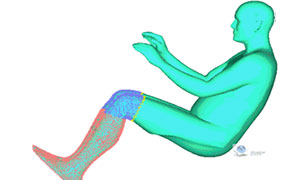

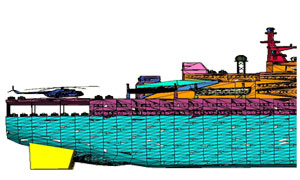

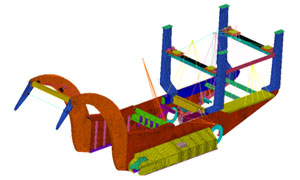

DEP’s engineering passion has resulted in the development of a software platform that is proprietary. The platform handles the electronics design parametrization of CAE models, CAE and CAD model generation, and CAD morphing. The DEP MeshWorks platform enables the optimization and rapid advanced-meshing in the process of teardown in PLM of CAE driven product development. The DEP MeshWorks platform manned by global and passionate engineers has created innovative solutions for very quick time to market products and has significantly accelerated the process of product development.

DEP services are world-class and customized for international clients across multi-sectors keeping in mind their very specific needs like product teardown that may be specific to their processes in Product Lifecycle Management.