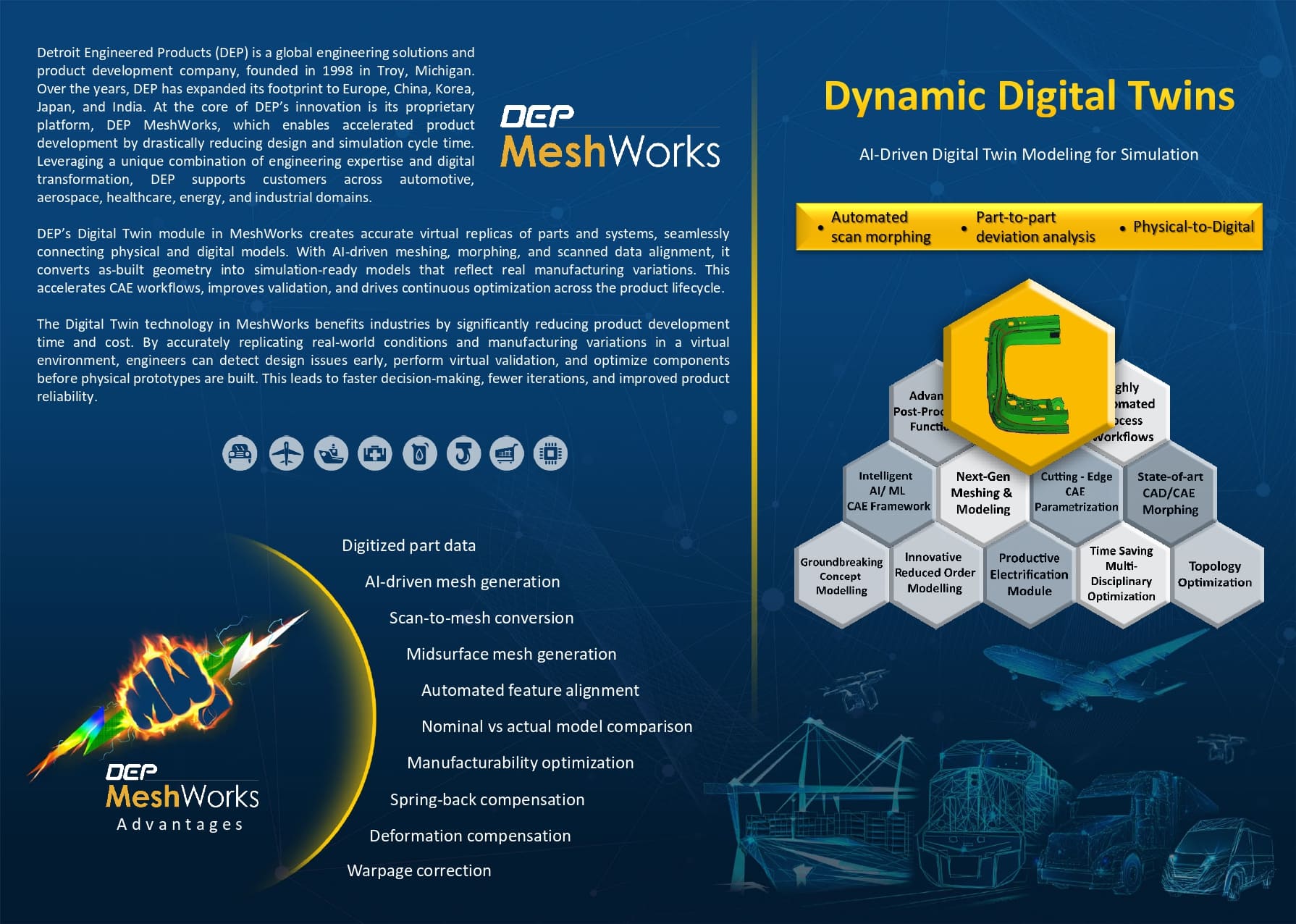

What Does Digital Twin Do?

The Efficient Digital Twin capability in MeshWorks enables automated, AI-driven mesh generation directly from digitized part and assembly data. By leveraging intelligent morphing technologies, this solution creates high-fidelity, defect-tolerant models that accelerate CAE workflows. Users benefit from faster parameterization, improved manufacturability, and optimized tooling performance – all within a seamless, fully automated process.

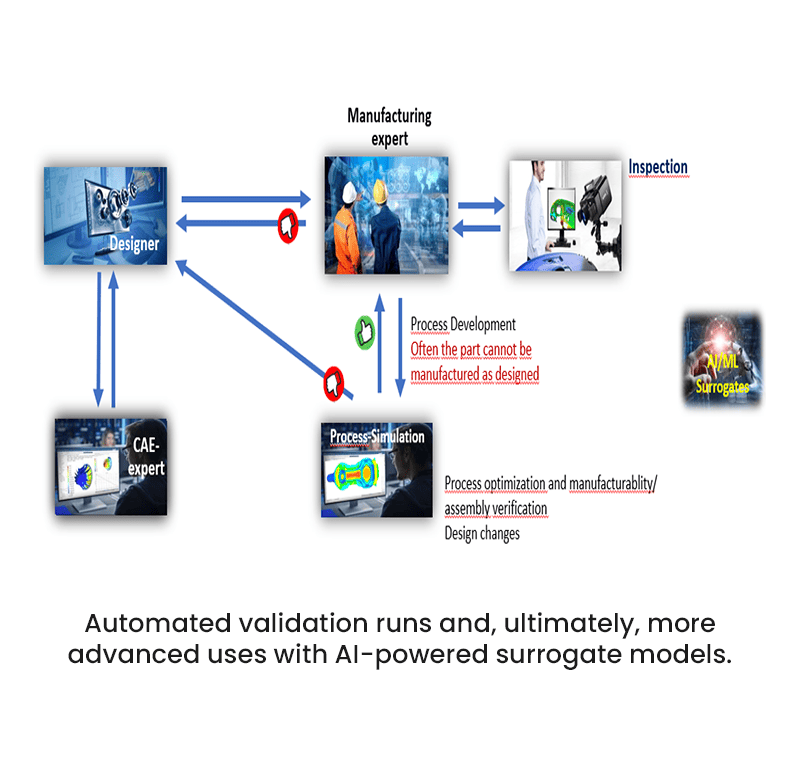

Manufacturing-Focused Design Optimization

Rapidly optimize parts, preforms, and tools for manufacturability and efficient assembly workflows.

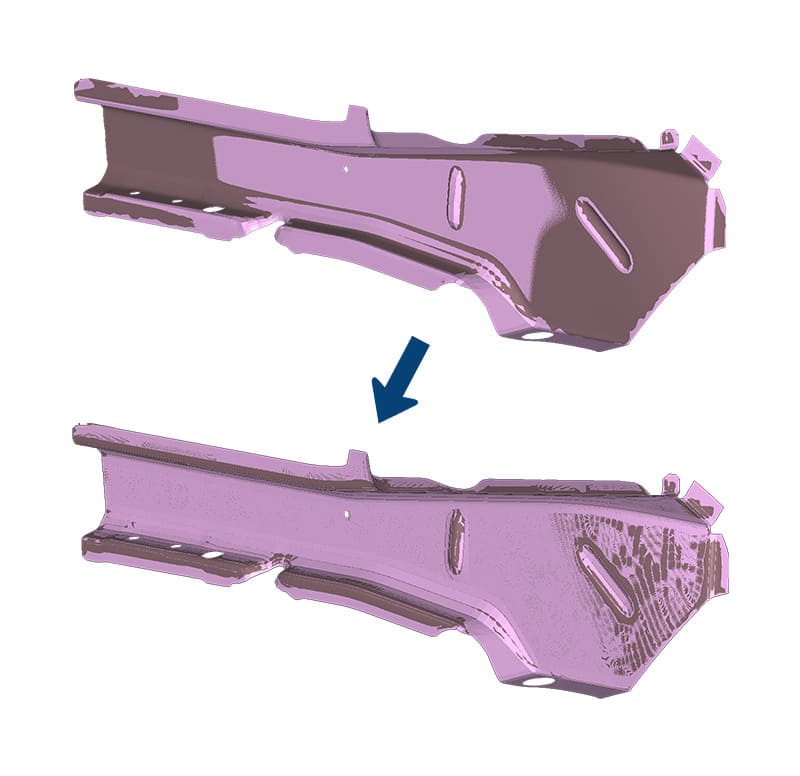

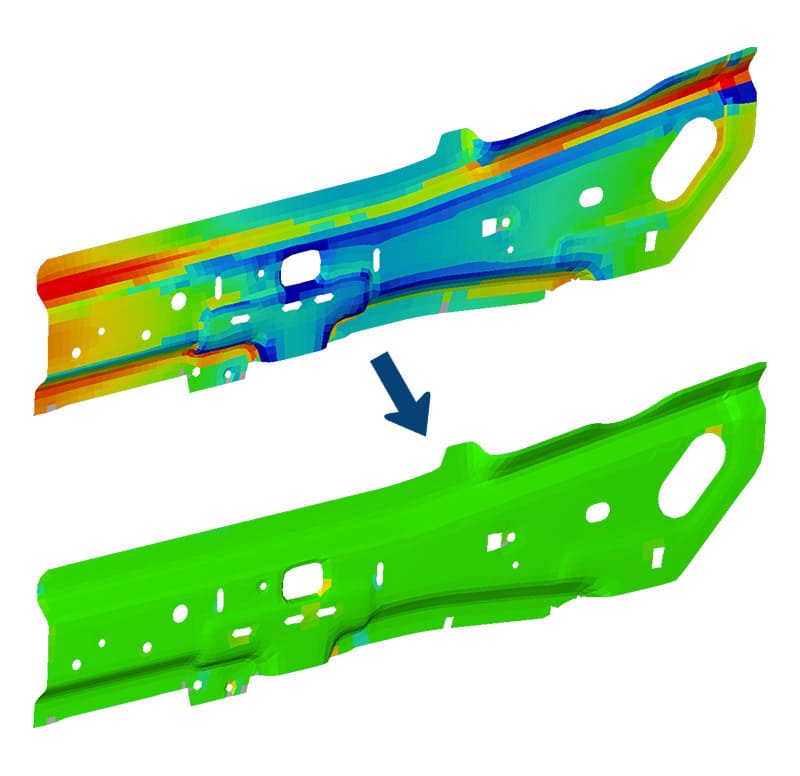

Automated Deformation Compensation

Automatically correct for common tooling issues such as warpage and spring-back.

Instant AI-Powered Simulation

Apply AI-based simulation updates in real-time following parametric design change.

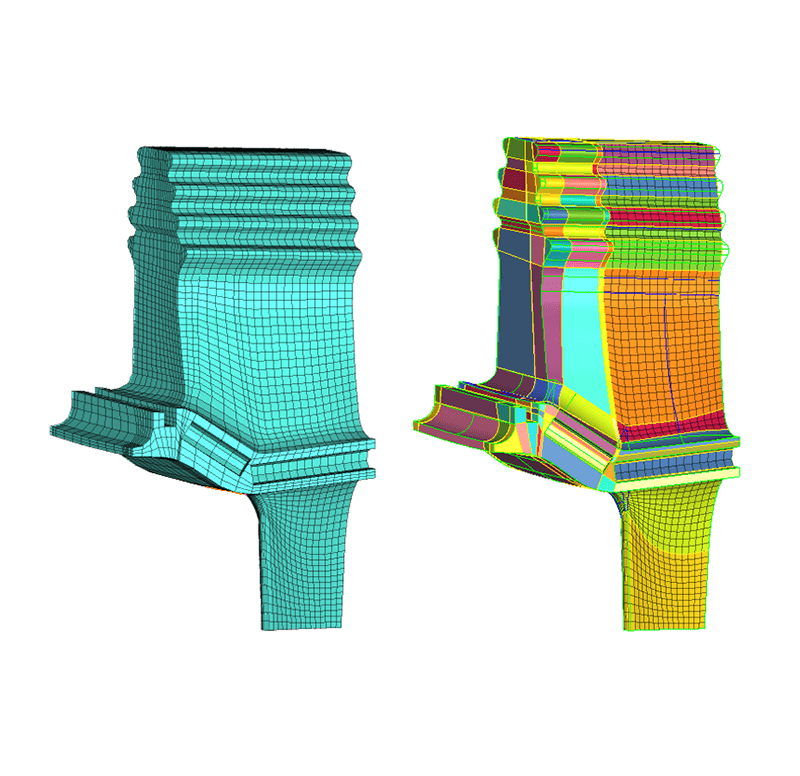

Intelligent Morphing Capabilities

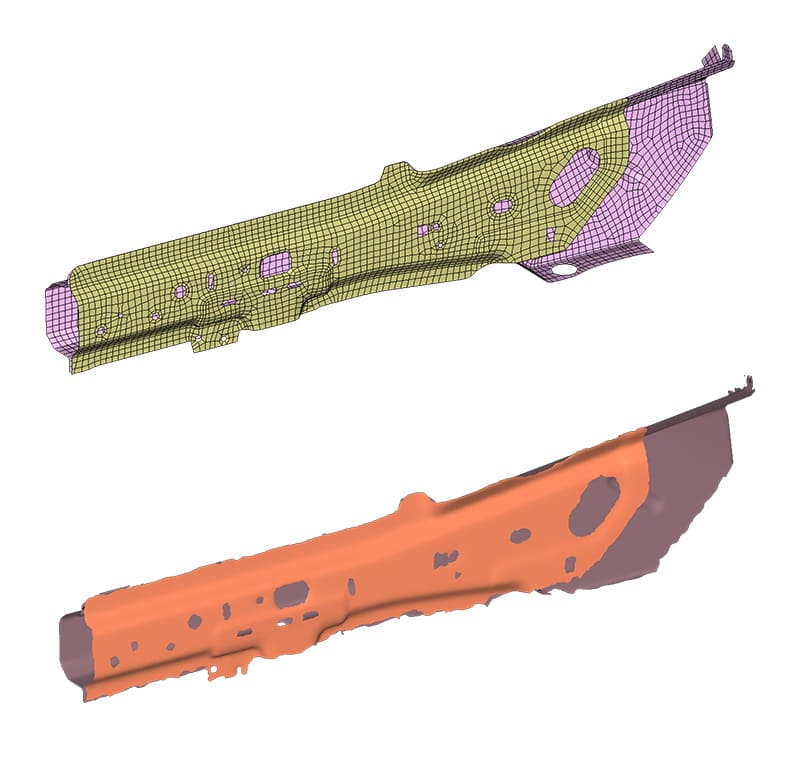

Transform scanned part data into accurate digital models using AI-guided mesh morphing.

Take a quick tour of

Digital Twin

Features of Digital Twin

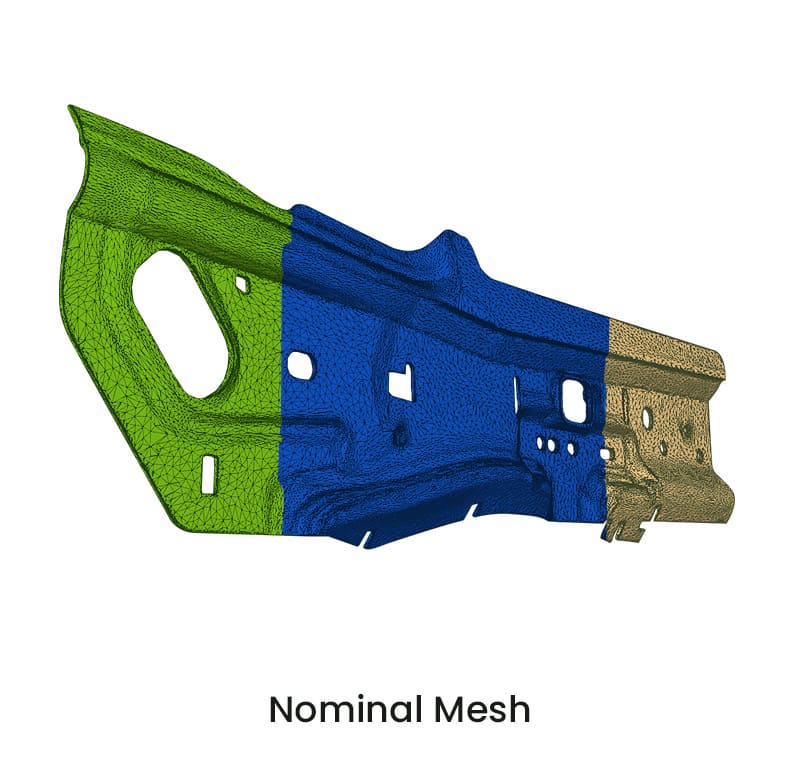

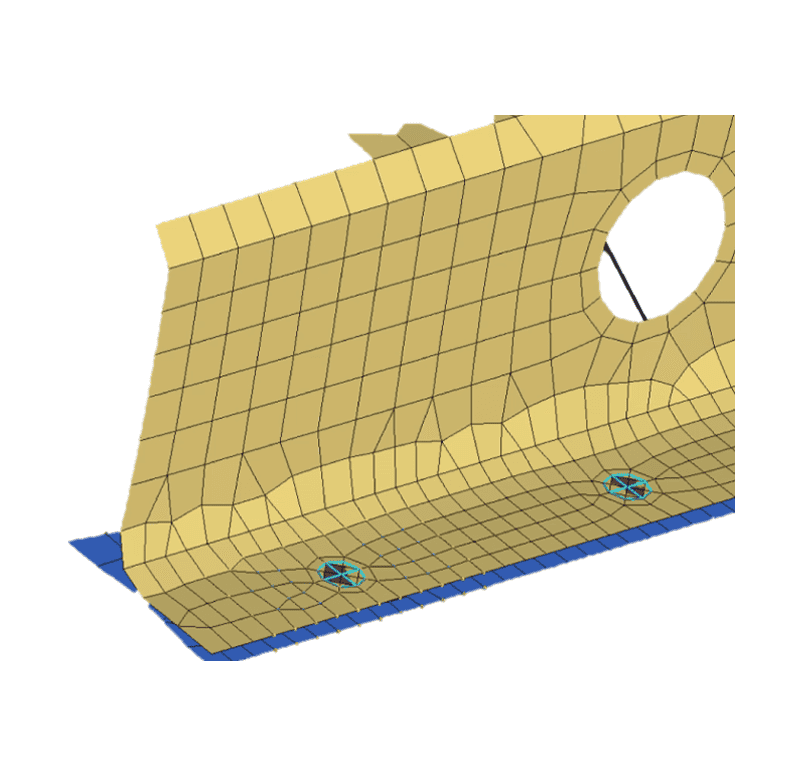

Scan-to-Mesh Conversion

Converts digitized scan data into mesh-ready models using robust morphing tools.

Automated Feature Alignment

AI algorithms automatically align scanned geometry with nominal CAD or mesh models.

Midsurface and Solid Mesh Generation

Generates both midsurface and 3D volume meshes with precision for downstream analysis.

Mesh Quality Enhancement

Improves element quality and mesh fidelity, increasing simulation accuracy and reliability.

Nominal vs Actual Model Comparison

Enables direct comparison of scanned and nominal models to evaluate manufacturing deviations.

Deformation Compensation Tools

Adjusts FE models for anticipated warpage and spring-back in forming or tooling processes.

DOE-Based Optimization Support

Integrates Design of Experiments (DOE) techniques for systematic part and tool improvement.

AI/ML Integration

Interfaces with MeshWorks’ AI/ML modules to enable predictive corrections and learning-based optimization.

Support for Assembly Components

Capable of handling entire assemblies in morphing workflows.

Get a Closer Look at

Get all the details about our CAE platform’s capabilities, technical specifications, and success stories.

MeshWorks Uniqueness

MeshWorks’ Efficient Digital Twin capability revolutionizes mesh generation by using AI-driven morphing to convert scanned or digitized data into simulation-ready models. It automates complex mesh transformations, compensates for manufacturing deviations, and significantly speeds up parameterization and optimization cycles. By automating and standardizing these processes, users can achieve up to 10x productivity gains while maintaining high levels of accuracy and design fidelity.

Automated Scan Morphing

Automatically morphs full FE models to align with scanned part data, minimizing manual intervention.

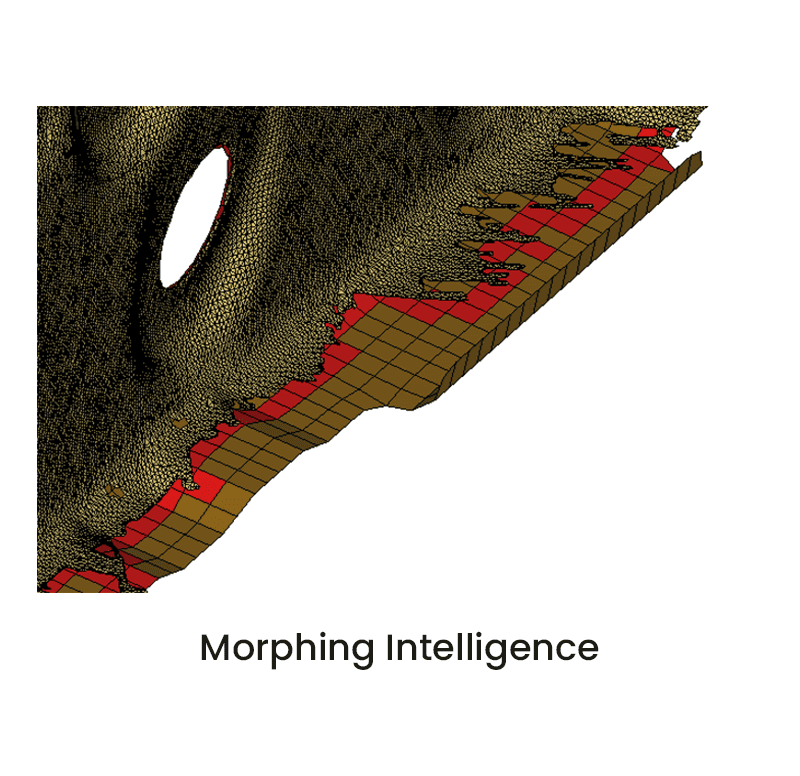

Intelligent Surface Detection

Recognizes target surfaces accurately—even in the presence of scan noise or surface irregularities.

Assembly Morphing with Gap Preservation

Maintains precise part spacing and stack-up order during full-assembly morphing operations.

Feature-Aware Mesh Alignment

Detects and aligns slots, holes, and circular features based on their center geometry, ensuring high-precision morphing.

Resources

Explore our library of resources to learn more

Ready To Transform Your

Product Development?

Join leading manufacturers who use MeshWorks to accelerate innovation, reduce development costs, and bring better products to the market faster.