What Does Meshing Do?

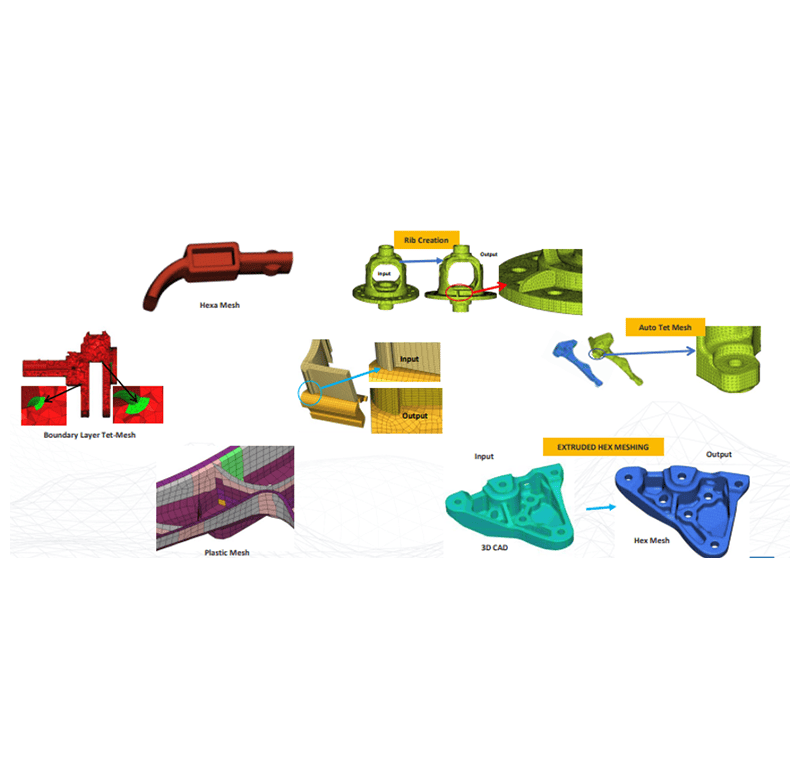

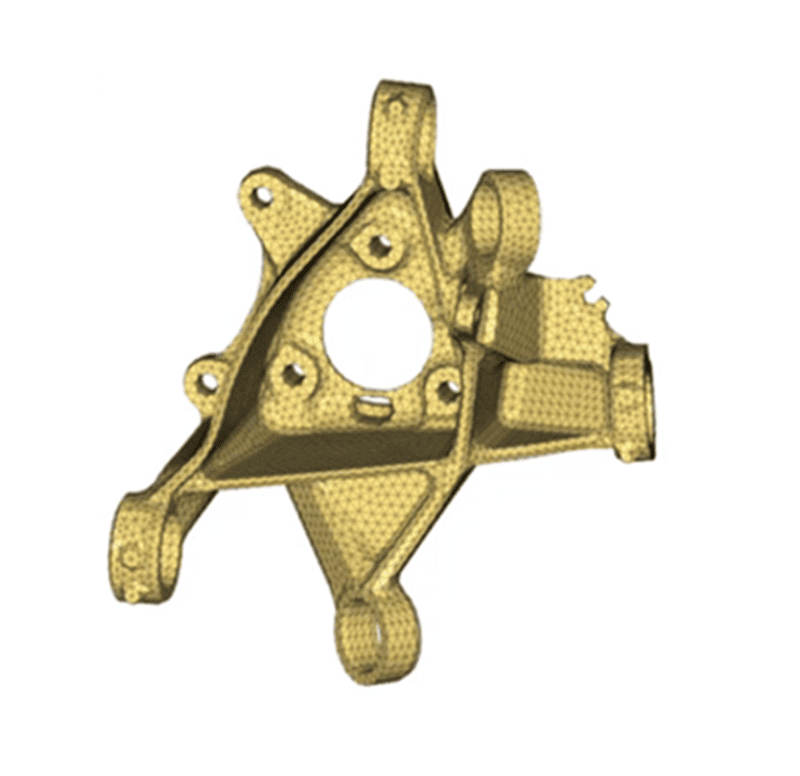

Designed for simulation professionals, the Meshing Module in MeshWorks provides a comprehensive environment for generating high-quality finite element meshes. It integrates multiple meshing techniques – including tetrahedral, hexahedral, quadrilateral surface, and mid-plane extraction—within a single platform. By leveraging AI-driven feature recognition and intelligent meshing templates, the module automates workflows, reduces manual effort, and maintains full associativity with underlying CAD geometry. This enables fast regeneration of meshes after design changes, improving productivity and adaptability throughout the simulation lifecycle.

Minimal CAD Cleanup

Mesh directly with minimal CAD preparation, eliminating time-consuming geometry corrections.

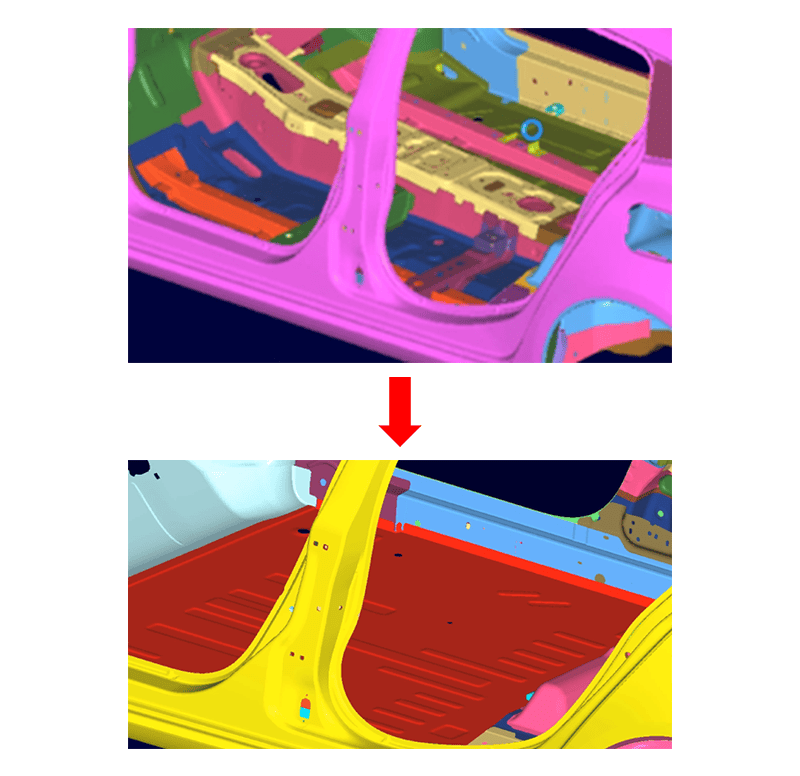

High-Speed Mid-Surface Generation

Mid-surface extraction delivers up to 50% faster performance than traditional methods, accelerating meshing cycles.

All-in-One Meshing Environment

Supports a wide range of meshing types—including tetra, hexa, plastics, and sheet metal—within a single unified framework.

Automated Batch Meshing

Enables system-level meshing through batch processes, maximizing speed and consistency across large assemblies.

Take a quick tour of

Meshing

Features of Meshing

Advanced CAE Meshing Tools

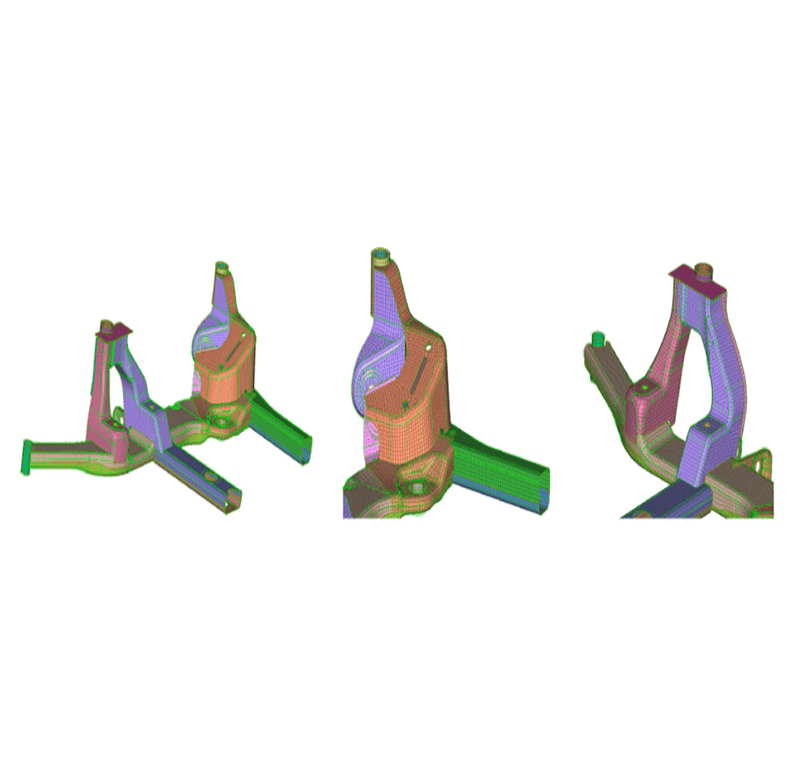

Quickly create 2D surface and 3D solid meshes (tetrahedral, hexahedral, mid-surface, sheet metal) from complex CAD models.

Automated Mesh Generation

High-level automation reduces dependency on manual CAD cleanup and accelerates mesh creation.

AI-Driven Geometry Recognition

Utilizes AI/ML to maintain geometric fidelity and intelligently handle complex features during meshing.

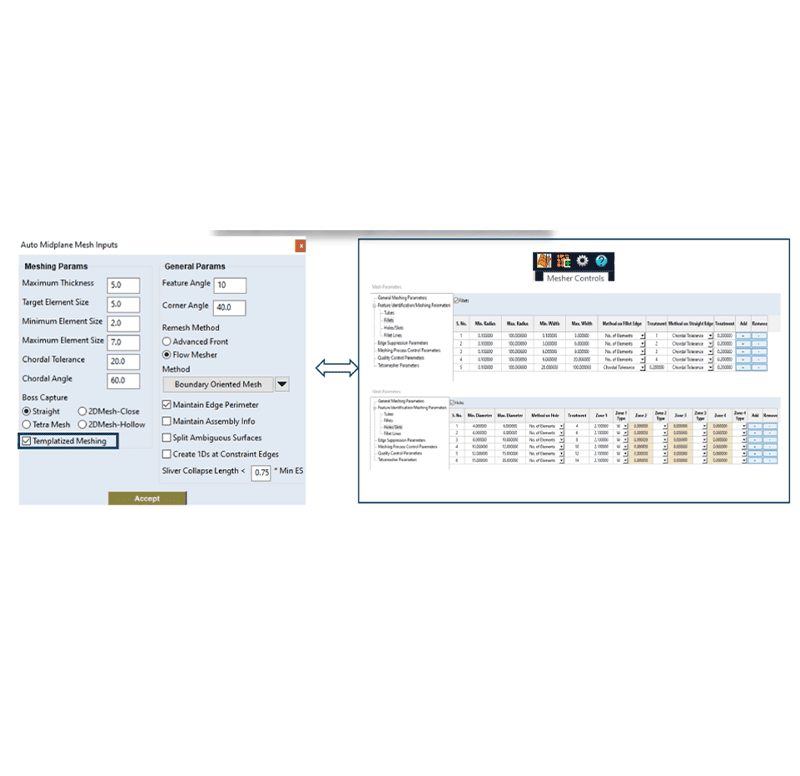

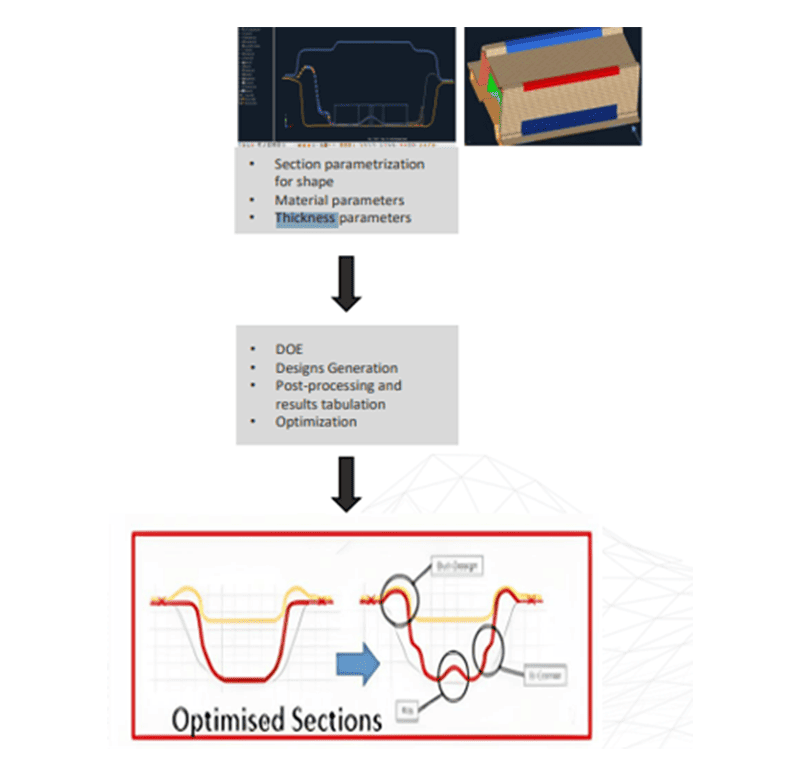

Template-Based Control

Apply predefined mesh settings to features like fillets, chamfers, tubes, and machined faces for consistent output.

Batch Meshing Workflow

Automates meshing for full assemblies and subsystems, delivering fast and accurate results with minimal input.

Mid-Surface Extraction Tools

One-click mid-surface creation with precise feature capture and optimal mesh flow.

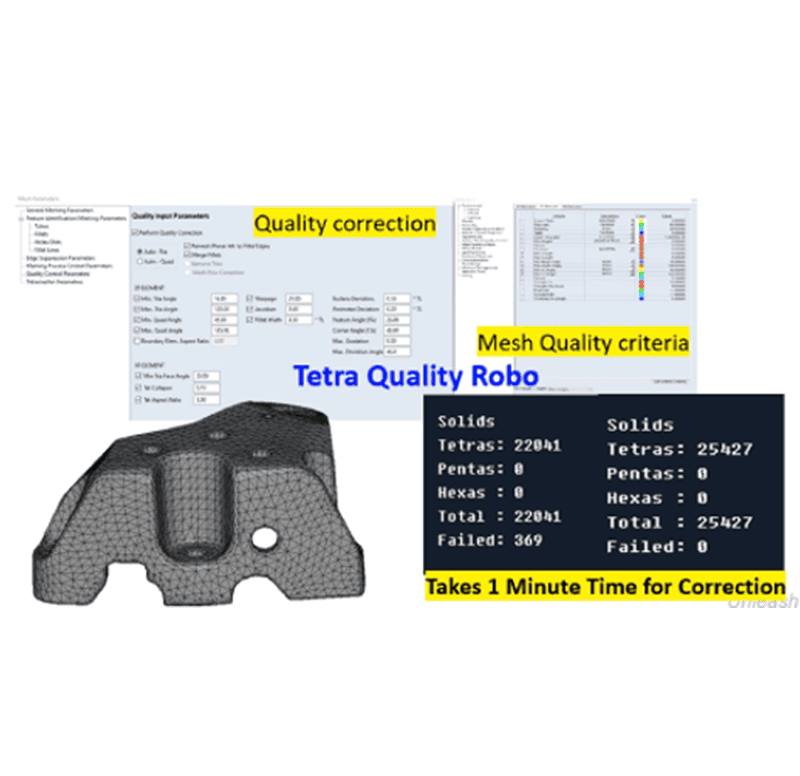

Automated Mesh Repair

Identifies and corrects over 50% of common mesh defects in a single pass, improving model readiness.

Flexible Thickness Application

Apply thickness data using automated strategies, including intelligent recognition of ribbed and complex sections.

Streamlined Meshing Workflow

Offers end-to-end meshing efficiency, reducing turnaround time while ensuring mesh quality and consistency.

Get a Closer Look at

Get all the details about our CAE platform’s capabilities, technical specifications, and success stories.

MeshWorks Uniqueness

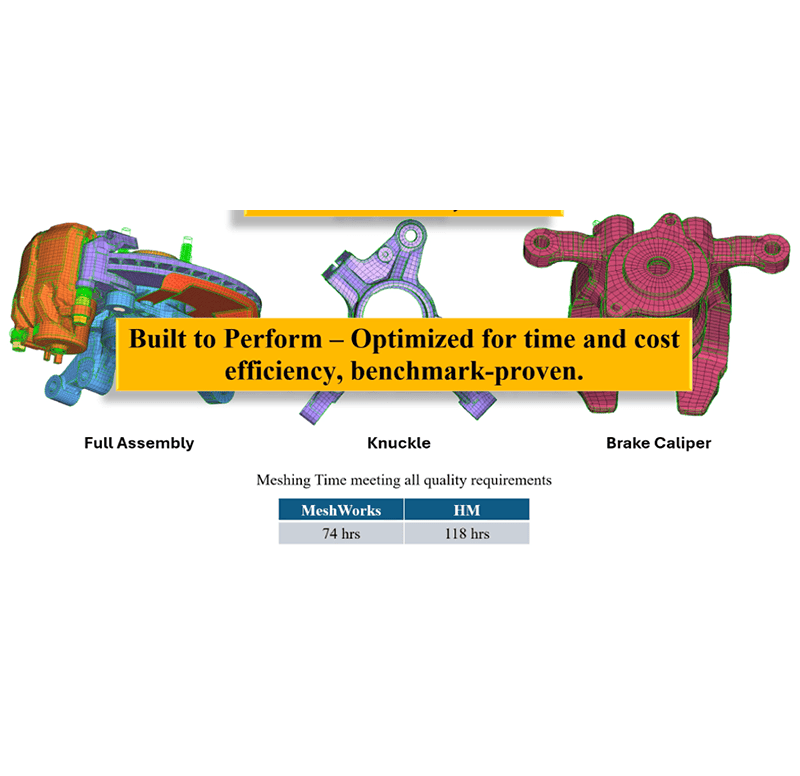

MeshWorks’ Meshing Module provides robust finite element meshing capabilities, enabling rapid creation of high-fidelity 2D and 3D meshes from detailed CAD geometry. With automated workflows powered by intelligent templates and AI-driven geometry processing, it minimizes the need for manual intervention. The module supports high-performance batch meshing for large assemblies and integrates seamlessly into HPC-based simulation pipelines. These features ensure scalable, repeatable, and production-ready mesh generation, enhancing overall engineering throughput.

Reduced CAD Dependency

Minimizes the need for geometry corrections, enabling direct meshing from raw CAD.

High-Quality Element Output

Generates superior mesh quality, enhancing simulation reliability and reducing rework.

Unified Platform Coverage

Supports all common meshing needs—tetrahedral, hexahedral, mid-plane, plastics, and sheet metal—within a single tool.

Cost and Time Savings

Eliminates the need for multiple meshing tools, lowering overhead and accelerating the development cycle.

Technical Brief

Deep dive into the technical strengths of MeshWorks Meshing functions with comprehensive detailing using explanatory videos

- Hexa Meshing Benchmark

- Hexa Meshing High Quality

- Hexa Meshing Industrial Grade

- Hexa Meshing Rapid Modification

- Hexa Meshing Multi-Industry

- Hexa Meshing Reuse

- Hexa Meshing Simple & Easy

- Hexa Meshing Depth Part

- Hexa Meshing Uniqueness

- Hexa Meshing User Experience (UX)

- Midplane Meshing Benchmarking

- Midplane Meshing High Quality

- Mid-plane Meshing Industrial Grade

- Mid-plane Meshing Rapid Modification

- Midplane Meshing Multi-Industry

- Mid-plane Meshing Reuse

- Mid-plane Meshing Simple & Easy

- Midplane Meshing Depth Part

- Mid-plane Meshing Uniqueness

- Mid-plane Meshing User Experience (UX)

- Sheet Metal Meshing Benchmarking

- Sheet Metal Meshing High Quality

- Sheet Metal Meshing Industrial Grade

- Sheet Metal Modification

- Sheet Metal Multi Industry

- Sheet Metal Reuse

- Sheet Metal Meshing Simple & Easy

- Sheet Metal Meshing Depth Part

- Sheet Metal Meshing Uniqueness

- Sheet Metal User Experience

- Tetra Meshing Benchmarking

- Tetra Meshing High-Quality

- Tetra Meshing Industrial Grade

- Tetra Meshing Modification

- Tetra Meshing Multi Industry

- Tetra Meshing Reusable

- Tetra Meshing Simple & Easy

- Tetra Meshing Depth

- Tetra Meshing Uniqueness

- Tetra Meshing User Experience

Download Our Meshing Resources

MeshWorks’ Meshing module is a powerful CAE engine that quickly generates high-quality 2D and 3D meshes from complex CAD data using automation, templates, and minimal cleanup.

Automated 2D and 3D meshing

Advanced hexahedral meshing tools

Batch and parametric mesh generation

Resources

Explore our library of resources to learn more

Ready To Transform Your

Product Development?

Join leading manufacturers who use MeshWorks to accelerate innovation, reduce development costs, and bring better products to the market faster.