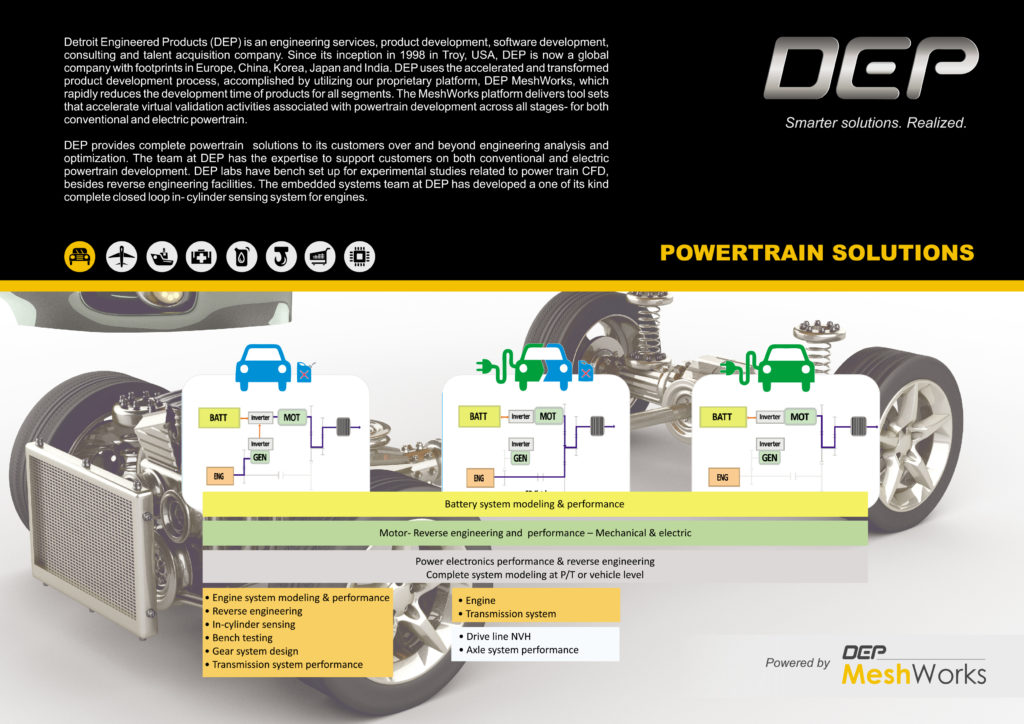

Powertrain Simulation:

Engineering a fuel and cost efficient vehicle demands a robust powertrain system and architecture. Designing such a powertrain is challenging, due to the highly complex, nonlinear, vibratory systems involved. This complexity is reflected in the number of gears, driving modes and degrees of comfort, which are increasingly required. Without compromising on performance, power and driving experience, the optimization of such systems necessitates the application of simulation in the design phase itself. Simulation leads to a deeper understanding of the system behaviour and helps to find successful solutions, while considering the interaction between all the individual components. It can comprehensively cover a variety of transport systems including ones driven by traction batteries and motors in electric vehicles (EV) and hybrid electric vehicles (HEV).

DEP MeshWorks– Powertrain Solutions:

Keeping with our vision of ‘CAE to lead design’, the team at DEP developed a powerful and robust simulation tool, DEP MeshWorks for automotive powertrain system design, simulation, and analysis. With decades of automotive experience backing us, the DEP team designed MeshWorks for modeling, designing, and scaling the electromagnetic, mechanical, and thermal characteristics of the components in a powertrain architecture. Our optimization methodology for powertrain design and development takes into consideration the cost, manufacturing methods and overall production volumes. With optimized parameters, powertrain development is accelerated and evaluated from the concept phase to production by simulation. Our holistic approach promises multi-attribute vehicle performance, by frontloading the powertrain-specific trade-offs at the component and sub-system levels.

Simulation continues to increase the proportion of virtual testing, and in-turn increases the efficiency of testing multi-fold.

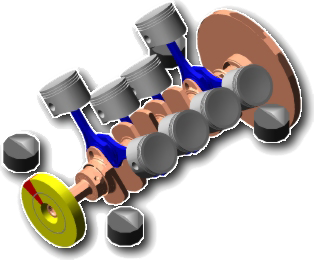

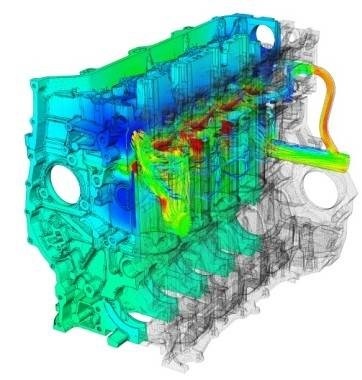

DEP MeshWorks Conventional Powertrain Capabilities: Our proprietary CAE platform, MeshWorks covers a full spectrum of powertrain system design for conventional vehicles. We optimize vehicle operation, fuel consumption, energy efficiency, and reduce the time to market with the below support solutions:

- Thermodynamics

- System Modeling

- Combustions Analysis

- Heat/Thermal Management

- Induction/Intake Management

- Block-head durability

- Crank-train dynamics

- Engine/Powertrain NVH

- Ventilation

- Lubrication

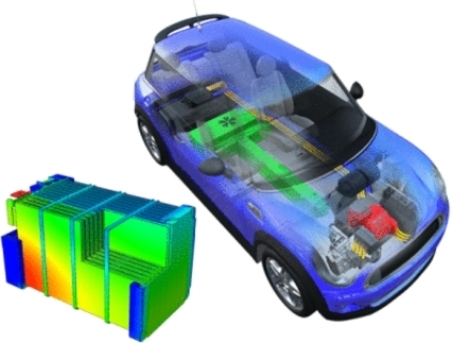

DEP MeshWorks Electric/Hybrid Powertrain Capabilities: We offer a wide range of simulation solutions for complex EV/HEV powertrain design that has significant impact on performance & efficiency:

- Electromagnetic analysis

- EV/HEV Traction Motor Simulation

- Coupled Control/Circuit Simulations

- Thermal demagnetization

- Thermal Analysis

- Motor

- Inverter

- Battery

- Structural analysis

- Durability and Fatigue Analysis

- NVH Analysis