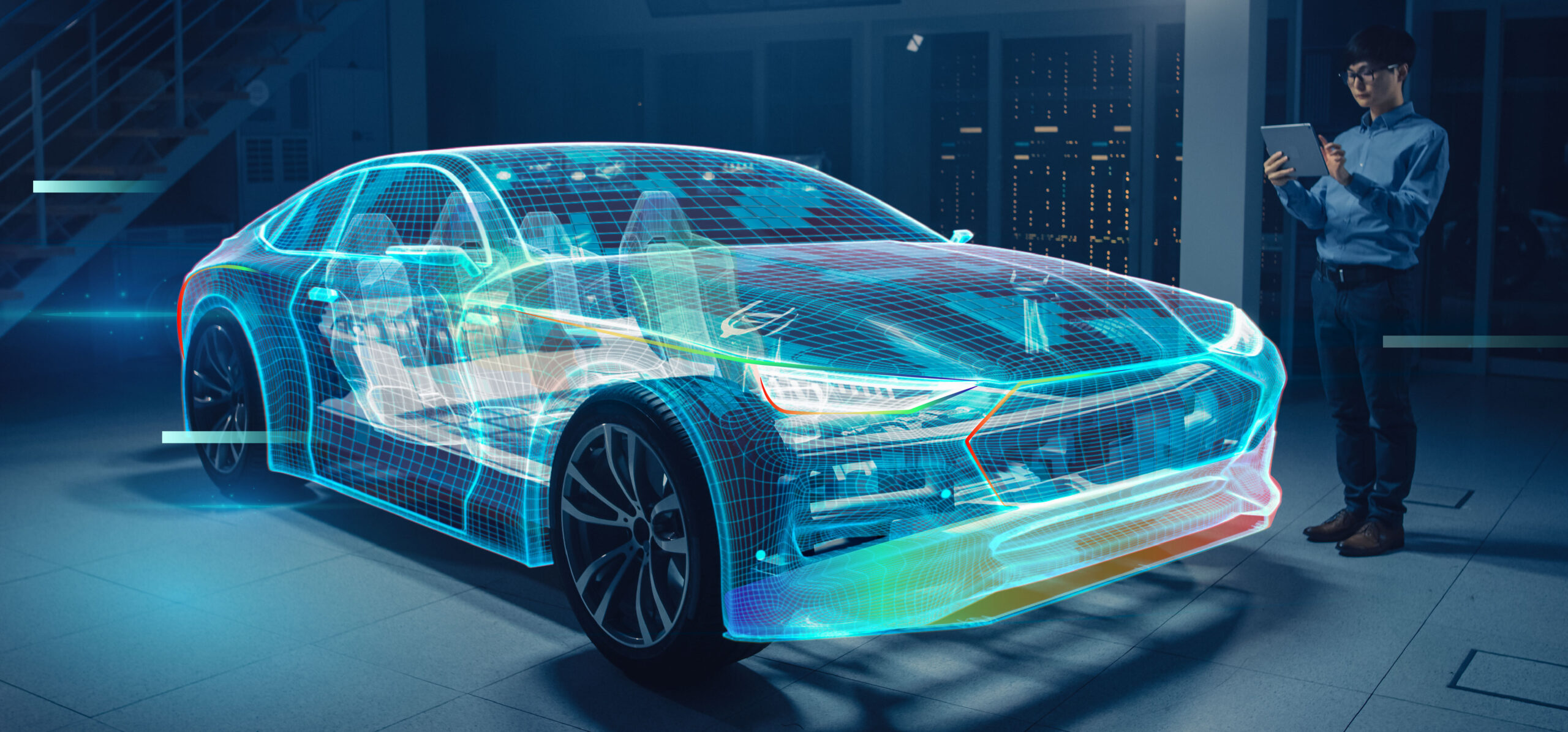

DEP MeshWorks 2023 is a game-changing CAE platform that’s set to disrupt the world of product development, by providing the power of next-generation CAE at your fingertips! Powered with cutting-edge toolsets for futuristic engineering that supports EV, ADAS application development, and backend technologies like AI/ML algorithms to enable rapid go-to-market strategies, it is a comprehensive and rock-solid CAE juggernaut.

With its inbuilt modules of lightning-quick concept CAE and CAD model generation, next-level meshing and morphing, simplified process automation, and advanced concept modeling, engineers can achieve outstanding results faster than ever before.

The latest power-packed version of MeshWorks makes it the ultimate and state-of-the-art suite of CAE solutions for product design and engineering.

DEP MeshWorks, developed by Detroit Engineered Products (DEP), is a platform that consists of pre and post-processing functions, encompassing separate toolsets for process automation, advanced meshing, rapid concept CAE & CAD model development, parameterization, and optimisation. The software has been utilized by leading companies across the world to transform the product development cycle and save considerable time and money, enabling faster entry into the market. Using MeshWorks has simplified tedious, time-consuming processes associated with design changes and reduced the product development cycle across multiple industry segments globally since its inception in 2001.

The latest version of DEP MeshWorks offers innovative solutions tailored for customized applications and product development processes. The present line-up of features and functions in MeshWorks supports overcome user challenges by providing a comprehensive end-to-end solution. Many of the MeshWorks modules are designed with unique capabilities utilizing several advanced algorithms/methodologies & AI/ML technologies in the backend that makes it ‘the best’ CAE platform in the current market. Our specialized modules starting from ConceptWorks, eMOD , to CAE parametrization, Multi-disciplinary optimization are created to aid engineers at all stages of product development. These features present themselves as a complete toolkit to enable product designers and engineers to rapidly develop, iterate, and optimize product designs. Additionally, MeshWorks gives the flexibility of faster design, more accurate simulation and enhanced engineering, improving the product from the get-go itself.

Some of our patented technologies focuses on significant impact on product design & development during the early stages, in-turn saving lot of time & effort of engineers. For instance, the CAD Morphing function, has been significantly automated to include both full vehicle level and sub-system level morphing. The FE/CFD pre and post processor engines coupled with engineering process automation reduce the time and manual labour involved in designing a product. With automation, there is increase in efficiency & performance at 30%-70% reduced time. MeshWorks allows users to tailor-fit the platform according to their specific needs through custom module functions. The advanced & innovative function in MeshWorks enables quick and easy methods to study the product design in an elaborate fashion and work on modifications, further accelerating the product development cycle. With MeshWorks we envision to help engineers develop future-ready products and optimize their design by applying the revolutionary CAE techniques.

MESHING

MeshWorks has a powerful CAE meshing engine that allows users to create 2D and 3D meshes rapidly from complex CAD data. Highly automated meshing functions available allow users to create exceptional quality meshes with minimal user intervention in the shortest time possible, with minimal to virtually no CAD clean-up.

Read More >>

MODELING

The Modeling module within MeshWorks comprises of a set of interactive and highly automated model assembly, model connection, materials, loads and boundary condition assignment functions that will allow users to create complex full system level models such as that of automotive vehicles, IC engines, airplanes, ships etc. in a highly condensed time frame.

Read More >>

POST PROCESSING

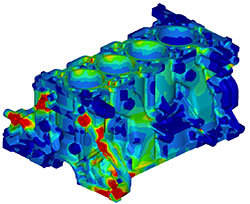

MeshWorks is a multi-disciplinary post-processor for viewing and publishing the results of analysis. It allows for loading and viewing the result files obtained from various solvers.

Read More >>

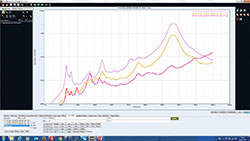

GRAPHING

MeshWorks graph is a powerful plotting and data analysis tool. It has a rich set of plotting features, a user friendly interface, easy navigation from function to function, and is fully integrated within the MeshWorks interface.

Read More >>

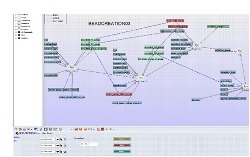

PROCESS AUTOMATION

Customer CAE processes can be rapidly automated using a fast Record > Create-GUI > Plumb > Publish process. Very complicated geometry and mesh creation processes can be automated with virtually no scripting or programming expertise.

Read More >>

CAE MORPHING

DEP MeshWorks is a feature based morphing tool that can rapidly morph existing FE and CFD models to match new geometry and/or to new proportions. Component and full system level FE/CFD models (such as automotive vehicle crash, NVH and durability models) can be morphed to fit target design features such as styling lines, sections, proportions etc. precisely.

Read More >>

CONCEPT MODELING

MeshWorks has advanced cutting, blending and stitching functions to create early stage concept FE and CFD models very rapidly.Local regions from the donor FE or CFD model can be cut, morphed and stitched to the target FE/CFD model resulting in a new concept quickly.

Read More >>

PARAMETRIC MODELING

MeshWorks is a comprehensive CAE model parameterization engine with a broad range of categories of parameters that can be used at all stages of product development.Regular FE/CFD models can be converted to intelligent parametric FE/CFD models. The parameters can be exercised as one-time execution or linked to DOE and MDO schemes.

Read More >>

DESIGN ENABLERS

MeshWorks has a powerful Design Enablers which enables rapid creation of finite element features such as ribs, holes, slots, reinforcements, bulk-heads, beads, darts, part-extensions/contractions, laser welded blanks etc. directly on FE/CFD models without the need for CAD.

Read More >>

MDO

DEP MeshWorks based parametric & non-parametric CAE models facilitate Multi-Disciplinary Optimization to meet design targets, minimize product weight and minimize manufacturing costs MeshWorks parametric models can robustly generate multiple runnable analysis data sets given a DOE matrix.

Read More >>

CAD MORPHING

The CAD morphing module allows users to morph existing CAD data (body structures, powertrain and chassis parts) directly to new shapes rapidly. It enerates morphed CAD models representing optimized designs very rapidly and forms the main link between CAE & Design teams, saving several months of CAD development.

Read More >>

Solver interface and supporting platforms

Supporting Platforms:

- Windows 64 bit (7,8,10)

- Windows Servers

- Red Hat and SUSE Enterprise Linux 64 bit (Workstation & HPC)

CAD Interfaces:

- Parasolid (text & binary)

- STEP

- IGES

- CATIA V4 & V5

- JT

- UG/ NX

FE Interfaces:

- STL (ASCII & Binary)

- MSC Nastran

- Abaqus FEA

- ANSYS

- LS-DYNA

- Pam-Crash

- RADIOSS

- Fluent

- SC/Tetra

- STAR-CD

- MADYMO

- OptiStruct

- GENESIS

- CONVERGE

- DEP Focuses on Both Products and Services – Basant Sharma, Vice President, DEP explains the different solutions and services from our portfolio

- DEP’s Full Vehicle Parameterization Technology reduces SUV weight, to making it fuel efficient

- Auto Component India Interviews DEP President, Radha Krishnan and Vice President, Basant Sharma about MeshWorks superior Modeling support for Tyre Industry