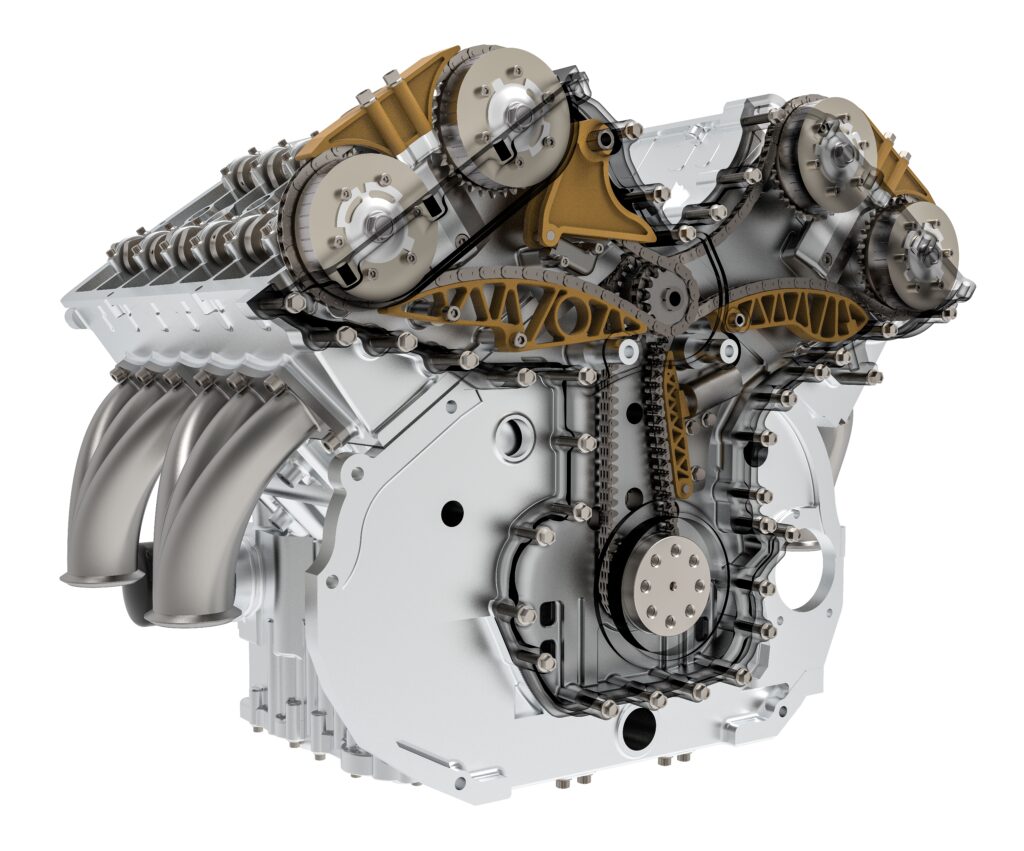

As automotive engineering evolves, the pursuit of creating powertrains with strength, agility, and fuel efficiency is endless. Computer-Aided Engineering (CAE) plays a critical role in this quest, signaling a new era in powertrain design characterized by accuracy and innovation. By combining innovative practice and creativity, CAE has provided car engineers with insights and tools to develop unbeatable performance and fuel efficiency powertrains. From structural analysis to fluid dynamics simulations, CAE is the basis for modern powertrain engineering, helping define today’s vehicles and setting the course for tomorrow.

Durability:

Block Head Durability: CAE assesses the structural integrity of blockheads under various operating conditions, including thermal and mechanical stresses. By simulating real-world scenarios, engineers can identify potential failure points and optimize the design to enhance durability and longevity.

Engine Mount Durability: Dynamic loads, vibrations, and thermal cycling of engine mounts are evaluated by CAE. By analyzing stress distribution and fatigue life, engineers can design mounts that provide optimal support while minimizing wear and tear on the powertrain.

Gasket Sealing Analysis: Gaskets in critical engine components, such as cylinder heads and intake manifolds, are simulated using CAE to ensure effective sealing and prevent leaks. By modeling compression, thermal expansion, and fluid dynamics, engineers can validate gasket designs for durability and reliability.

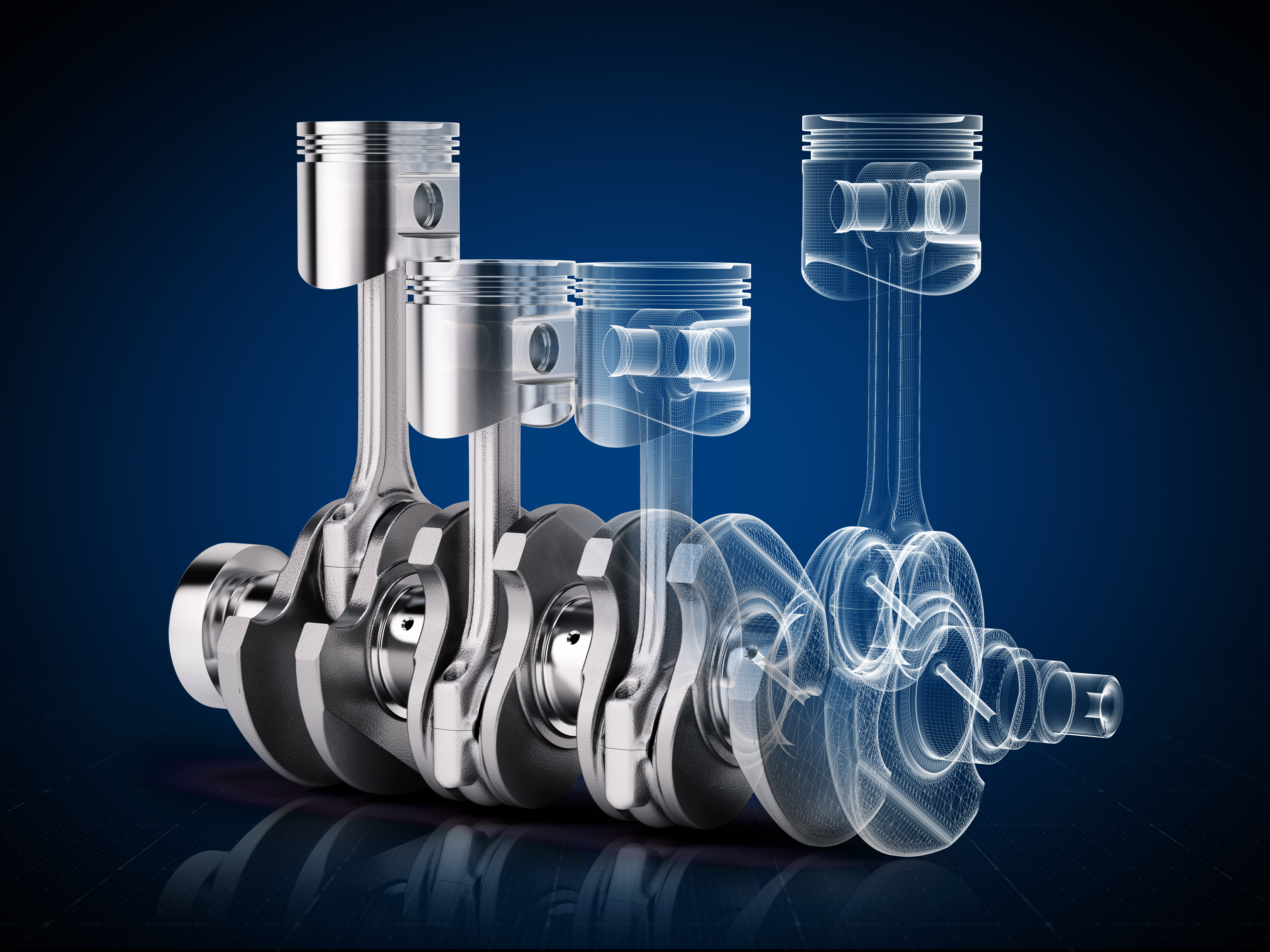

Engine Components Structural Analysis: CAE conducts structural analysis of engine components such as pistons, connecting rods, and crankshafts to assess their ability to withstand forces and loads during operation. By identifying weak points and stress concentrations, engineers can refine designs for improved durability and performance.

Rotating/Reciprocating Components Structural Analysis: The structural integrity of rotating and reciprocating components CAE evaluates, such as camshafts, crankshafts, and bearings. By analyzing dynamic forces, fatigue, and wear patterns, engineers can optimize designs to enhance durability and reduce the risk of component failure over time.

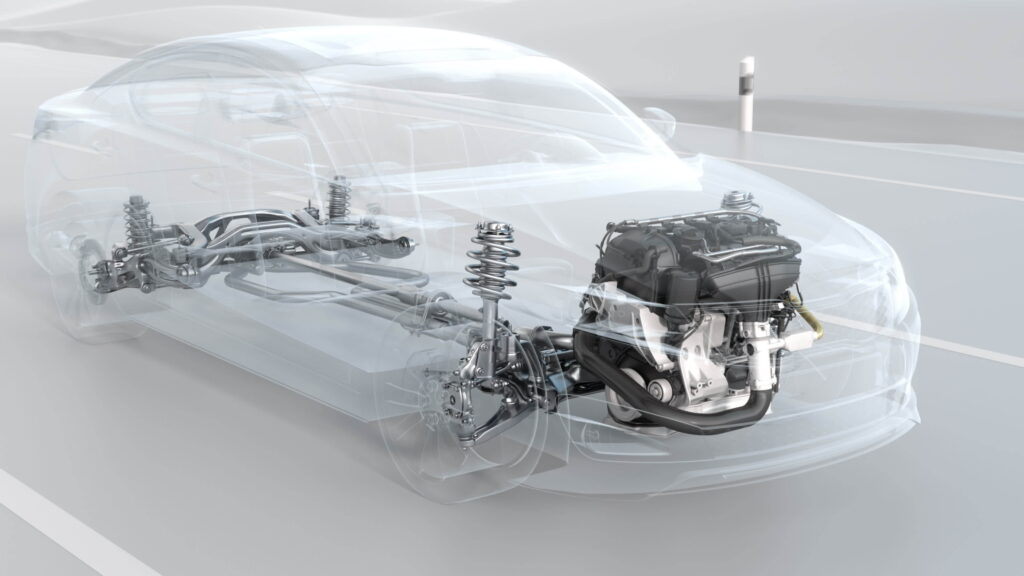

Optimizing Powertrain NVH: Noise, Vibration, and Harshness (NVH) affect vehicle comfort and driving experience. CAE enables detailed simulations of powertrain components to address NVH issues. Modal analysis identifies natural frequencies and vibration analysis evaluates engine excitations’ impact, guiding the design of NVH countermeasures for a smoother, quieter ride.

Advancing Transmission and Driveline Design

Transmission and driveline systems require balancing performance, efficiency, and durability. CAE analyzes gear tooth contact, lubrication, and thermal effects. Multibody dynamics simulations optimize gear ratios, shift strategies, and driveline layout for seamless power delivery, reduced friction losses, and improved fuel economy.

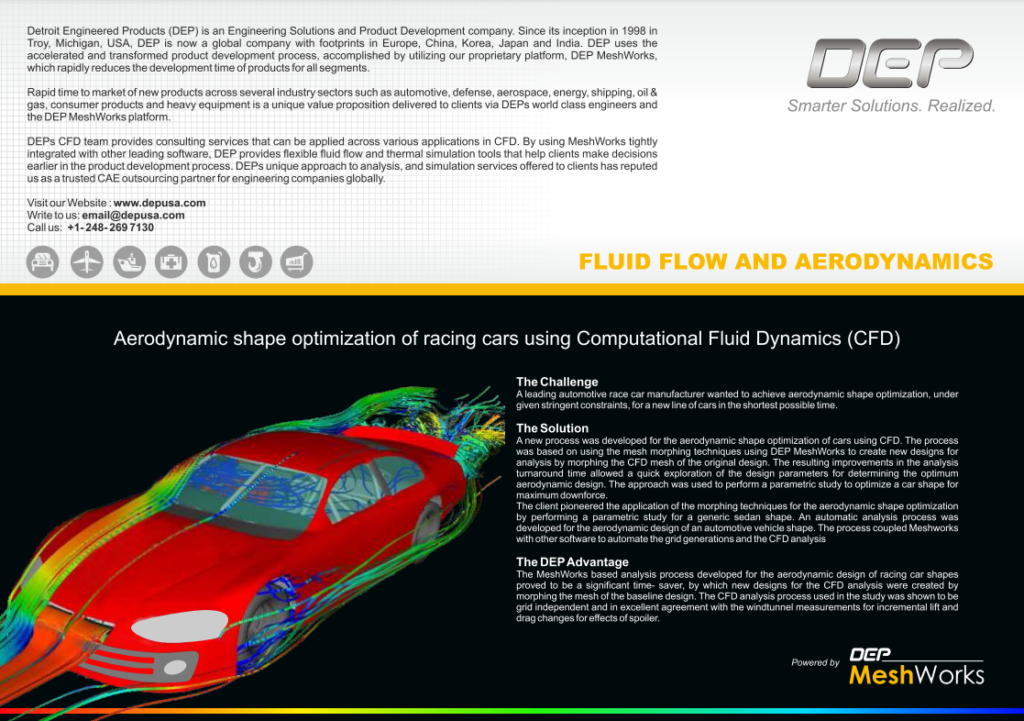

Engine CFD: A Comprehensive Approach

Engine Computational Fluid Dynamics (CFD) analyses enhance performance and efficiency through:

- Powertrain 1D Simulations: Modeling system-level interactions between engine, transmission, and driveline to optimize architecture, control strategies, and thermal management.

- Intake & Exhaust Systems: Optimizing airflow dynamics, pressure drops, and temperature distributions to improve engine breathing, reduce backpressure, and enhance emission performance for better fuel efficiency and lower emissions.

- Thermal Analysis: Modeling heat transfer processes within the engine to guide cooling system design, prevent overheating, and enhance engine performance and fuel economy.

- Engine Combustion: Simulating fuel injection, air-fuel mixing, flame propagation, and pollutant formation to optimize combustion chamber design, injection strategies, and ignition timing for more efficient and cleaner combustion

Specialized CFD Analyses:

- Oil Mist Separation Analysis: Modeling oil droplet behavior to design effective separation systems, reduces emissions and oil consumption for enhanced engine durability.

- Torque Converter CFD Analysis: Simulating fluid flow, pressure distribution, and heat generation in torque converters to optimize the design for improved efficiency and smoother power delivery.

- Engine Oil Circuit Analysis: Modeling lubricating oil flow to ensure adequate lubrication, reduce pressure drops, and improve engine performance and longevity.

The Advantages of CAE are numerous:

- Reduced Development Time:

Gone are the days of waiting weeks for physical prototypes. CAE allows for rapid design iterations, accelerating development cycles significantly.

- Cost Savings:

Building and testing prototypes can be expensive. CAE virtual testing eliminates these costs, leading to significant financial savings.

- Improved Engine Performance:

CAE allows engineers to explore a wider range of design possibilities and optimize for specific goals like fuel efficiency, power output, or emissions reduction.

- Enhanced Reliability:

By identifying potential weak points early on, CAE helps create more robust and reliable engines.

Innovating Engine Design with Detroit Engineered Products’ CAE Solutions

DEP’s approach integrates advanced CAE methodologies with extensive research and development to deliver high-fidelity digital simulation models. These models encompass various aspects such as performance, thermal management, fuel economy, after-treatment systems, lubrication systems, and competitor benchmarking.

DEP’s CAE-based Engine Design Advantages:

Comprehensive Optimization Approach:

DEP’s CAE solutions encompass a range of optimization strategies including performance optimization, component optimization, mass efficiency strategies, and engine testing. Through advanced CAE functionalities such as thermodynamics, systems modeling, combustion analysis, and heat/thermal management simulations, DEP ensures the development of high-quality engines.

Value enablers:

- Significant Emission Reduction

- Mechanical Effectiveness

- Efficiency of Thermodynamics

- Fuel Conversion Optimization

DEP’s CAE-based engine design solution is not just about meeting current automotive challenges but also about paving the way for the future of sustainable and efficient transportation. With a commitment to innovation and excellence, DEP empowers automotive manufacturers to stay ahead in an ever-evolving industry landscape.