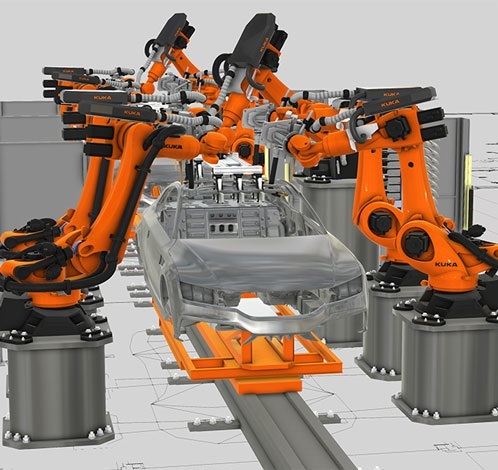

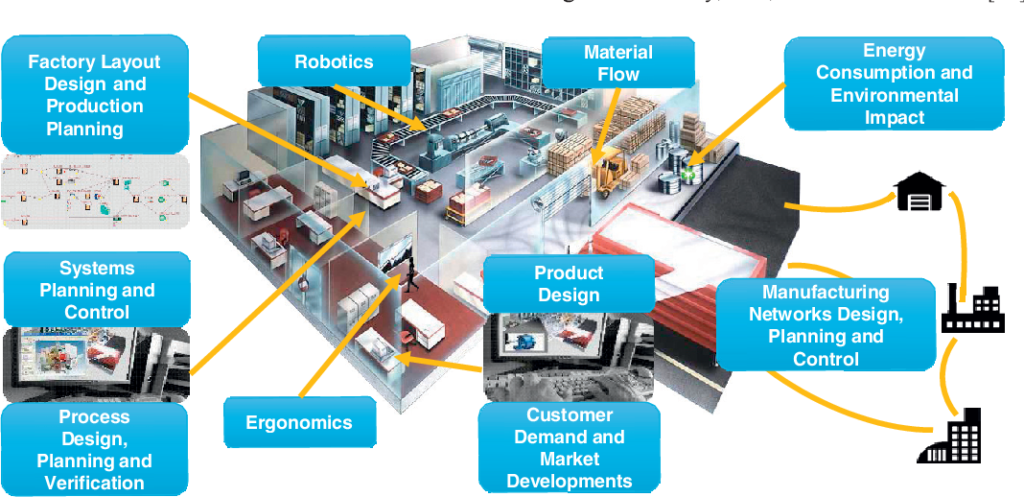

The need for efficiency in the manufacturing industry has increased and successful companies must analyse and optimize expenses associated with time, equipment and other investments. Simulation modelling and analysis is a cost-effective decision-making tool that enables you to understand and visualize the effects of change and the expenses associated with them prior to implementation. DEP’s Manufacturing Simulation enables companies to create well-structured, hierarchical models of production facilities, lines and processes. Clients in a wide range of industries, including automotive, healthcare, retail, and manufacturing, have benefited from our unique simulation techniques and extensive expertise in diverse simulation projects.

DEP Value Addition:

- A powerful combination of engineering and technology helps make confident and informed decisions

- Maximizing return on investment with evaluation report from planning to implementation stage

- Data-driven strategies to monitor, simulate, and evaluate production strategies to improve performance

- Improve resource utilization and shorten go-to-market timelines for positive revenue results

DEP can assist you in the following areas of Simulation:

- Production planning optimization

- Facility design and balancing of assembly line

- Bottleneck and process improvement analysis

- Ergonomics related constraints analysis

Customer Benefits:

Supported by the ease of use and modeling flexibility from technology tools perspective, DEP is a valued partner for all simulation projects. Customers are proven to benefit from:

- Upfront virtual validation reducing the need for physical prototypes

- Minimized risk by simulating ample manufacturing scenarios

- Optimized production time with the help of simulation

- Enhanced financial benefits from early deduction of design issues