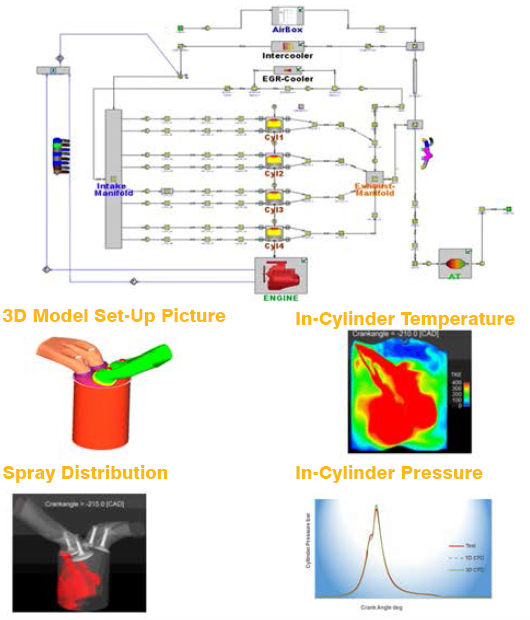

Modern automobiles will be expected to increase their economy, minimize CO2 emissions, and achieve excellent levels of driving, safety, and noise performance. Vehicles will be equipped with advanced hardware, sensing monitors, and emission control in order to reach high levels of performance and ability to operate on a wider variety of fuel characteristics. Multiple iterations of simulations should be carried out to calibrate the model with test data for performance, fuel economy and emissions. The simulation focuses on performance optimization of the PCV system by accurately matching the ventilation flow with the blow by production characteristics, while engine performance and drivability remain unaffected.

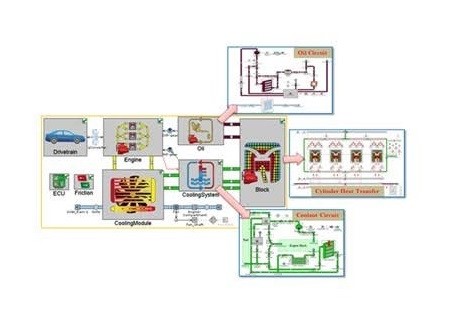

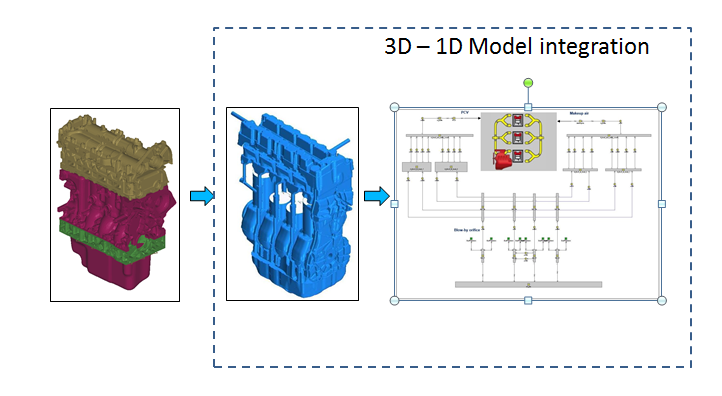

DEP does extensive research and development work for advanced powertrain development using the Model based system engineering approach. DEP provides CAE Solutions with a high fidelity digital simulation model for performance, thermal management, fuel economy, after-treatment system, lubrication system and competitor benchmarking.

Key Distinguishers:

DEP engineers develop a high efficiency GCI engine

DEP aims to combine the benefits of a diesel engine (high thermal efficiency) and gasoline as a fuel (lower emissions) with low-temperature combustion and best-in-class fuel economy.

DEP Engine Capabilities:

- Packaging

- Manufacturability

- Ventilation Performance

- Cooling Performance

- Lubrication Performance

- Part & Combustion Chamber Optimization

- Cranktrain Dynamics

- Intake Manifold optimization

- Engine Performance

- Powertrain NVH

- Fuel injection Strategy.

- Increased CR

- Combustion chamber design

- Fuel selection

DEP Advantages:

An highly efficient engine should require performance optimization, components optimization, mass efficiency strategy, engine testing, and general CAE functionalities like thermodynamics, systems modeling, combustion, heat/thermal management, induction/intake, block-head durability, crank-train dynamics, engine/powertrain NVH, ventilation, lubrication, etc. With our expert services, we provide a complete suite of services that aims to increase the quality of engines that are being developed

Customer Benefits: