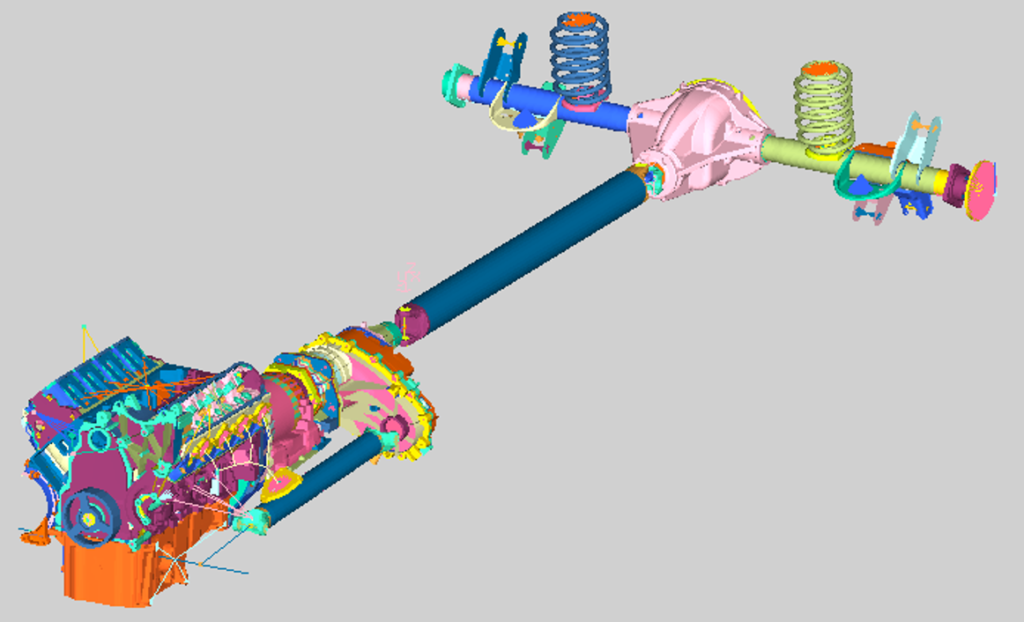

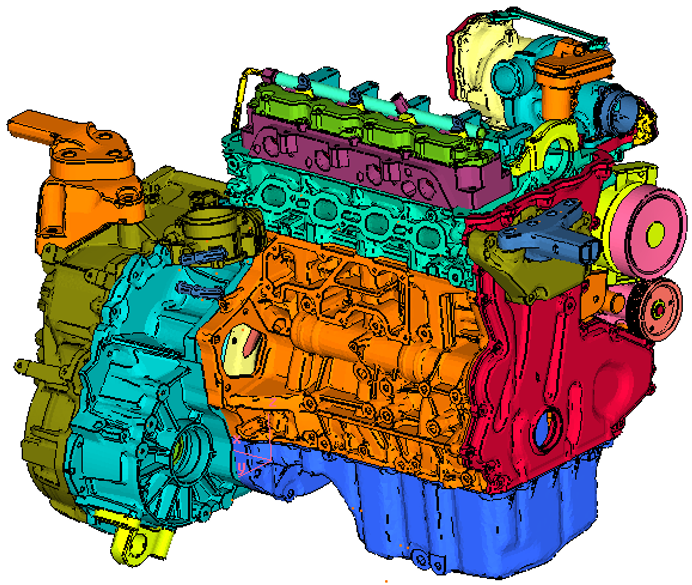

Modern engineering is extending its capabilities for end-to-end optimization of full vehicles starting from body structures, chassis, and wheels to powertrain and related analysis. Engineering a robust powertrain is challenging, due to the highly complex, nonlinear, vibratory systems involved. With decades of automotive experience backing us, DEP’s experts team designed MeshWorks for modelling, designing, and scaling the electromagnetic, mechanical, and thermal characteristics of the components in a powertrain architecture. Our optimization methodology for powertrain design and development takes into consideration the cost, manufacturing methods and overall production volumes. By frontloading the powertrain-specific trade-offs at the component and sub-system levels, our holistic approach offers multi-attribute vehicle performance.

We optimize vehicle operation, fuel consumption, energy efficiency, and reduce the time to market with the below support solutions:

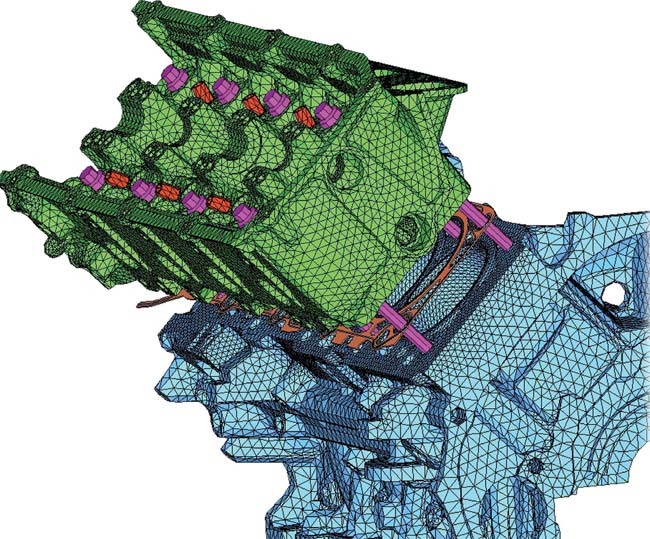

- Durability:

- Block head durability

- Engine mount durability

- Gasket sealing analysis

- Engine components structural analysis

- Rotating/Reciprocating components structural analysis

- PT NVH:

- PT Bending analysis

- Engine Assembly NVH

- Engine mount dynamic stiffness

- Accessory NVH

- Radiated Noise

- Rear axle stress & NVH analysis

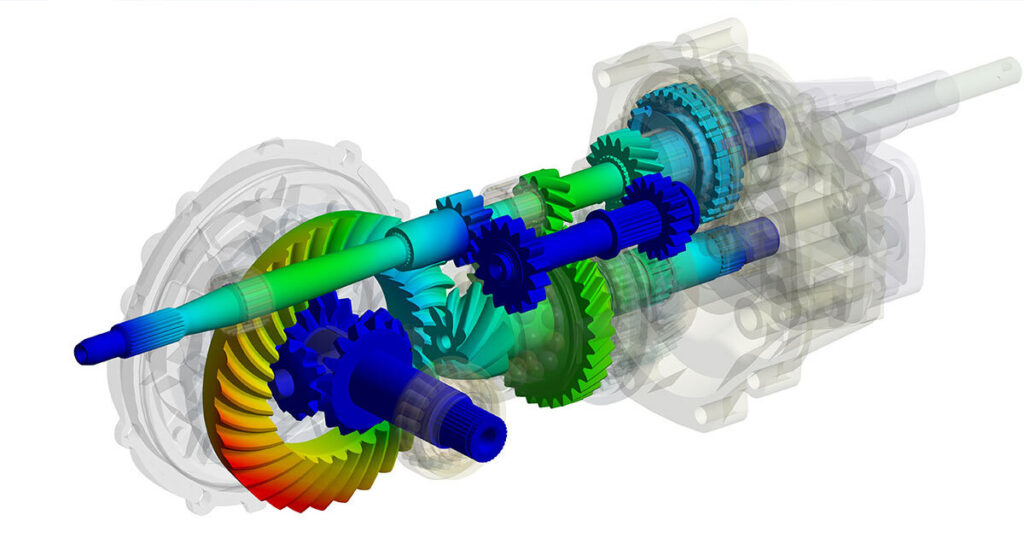

- Transmission and driveline:

- Transmission Housing Durability

- Front/rear Axle Durability

- Diff. case Durability

- Transmission assembly NVH

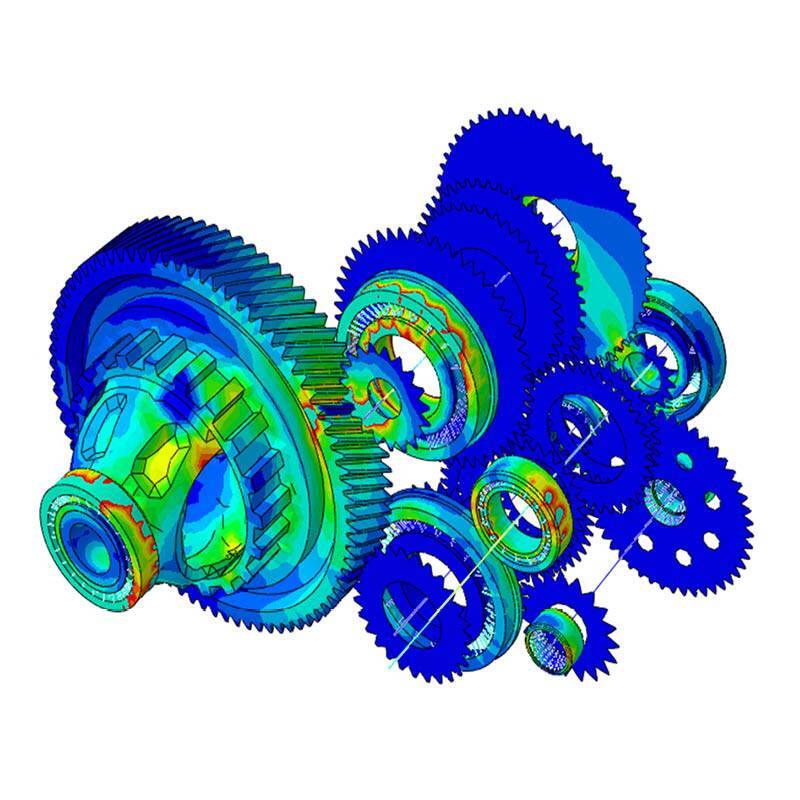

- Transmission gear train modeling & analysis

- Transmission sealability

- Engine CFD

- Powertrain 1D Simulations

- Full engine performance, prediction & validation

- PCV ventilation analysis

- Oil lubrication system

- Piston lube oil consumption

- Full Fuel injection system

- Piston skirt friction EHD

- Camshaft bearing EHD

- Intake & Exhaust Systems

- Intake & Exhaust Port flow and Manifold Analysis

- Throttle Body Analysis

- Exhaust Manifold CHT Analysis – thermal Load

- O2 Sensor Placement Analysis

- Turbocharger Compressor Map Generation

- EGR and MAP sensor Analysis on Intake Manifold

- Air induction system analysis

- Engine oil pump performance analysis

- Thermal Analysis

- Engine breathing simulation

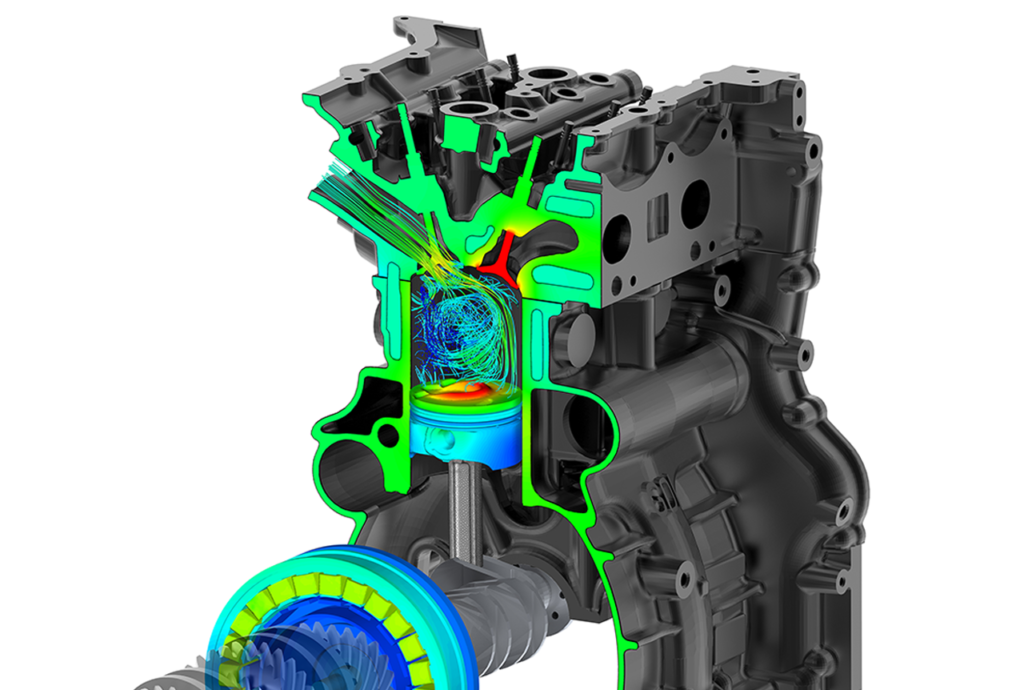

- Piston cooling via oil jet analysis

- Engine coolant side CFD simulation

- Parametrization of CFD models

- Engine Combustion

- Engine Combustion analysis

- Flame Propagation – MBT50

- Effect of Cylinder Turbulence

- Intake port steady flow analysis

- Other CFD Analysis

- Oil mist separation analysis

- Torque Converter CFD analysis

- Engine oil circuit analysis

- Other typical analyses includes:

- Engine sealability

- Mount and accessory bracket tuning

- Crank train Multi-body Dynamics

- Clutch assembly modeling and analysis

- Park pawl system MBD & Stress analysis

- Gear shift mechanism MBD & Stress analysis

- Powertrain bending dynamics

- Powertrain torsional dynamics

- Topology optimization & shape optimization