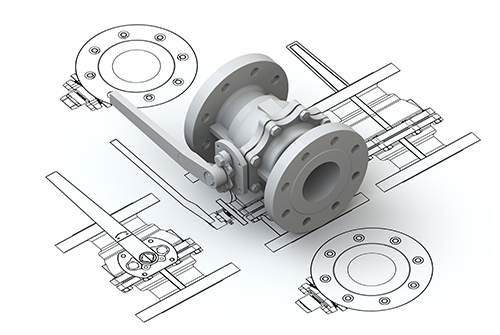

Getting any product idea off the drawing board to a tangible reality takes shape when a 2D or 3D model of a concept is made. With prototype processing, we can continue to make modifications at a lower cost and in less time until we have a clear picture of the expectations and needs. At DEP, we make sure the model feels appropriate and embodies the attributes that are selected by the customers. With our vast facilities in labs and workshops, we can satisfy our clients and ensure that the products integrate attributes necessary for success. DEP’s expert team can help you with every step of product development, from optimizing your design to efficiently reviewing the functionality of the product before mass production. We create cost-effective and high-quality prototypes by combining a specialized range of technologies and services. DEP supports manufacturers to improve and enhance products by identifying and reducing design flaws without investing heavily in volume production.

DEP Value Addition:

- Industry-Leading Expertise with an International Presence

- Fast turnaround time with prototype parts with utilization of high resolution 3D Printing technologies, molding solutions, etc.

- Rapid iterations that produce concrete ideas and tangible prototypes that can be viewed, assessed, tested, and refined.

- Get-to-market faster with early on engineering and user testing of your design concepts that rules out major design, function, and cost issues.

- State-of-art facility combined with technology helps you shape your ideas using trusted materials and techniques.

DEP Prototyping services:

We offer on-demand prototyping services and assist clients in their engineering-design needs in every step of product development process:

- Concept Design – Optimal product concept solution

- 3D CAD product concepts

- Evaluation mock-up for non-operational prototype

- Scalable Proto builds

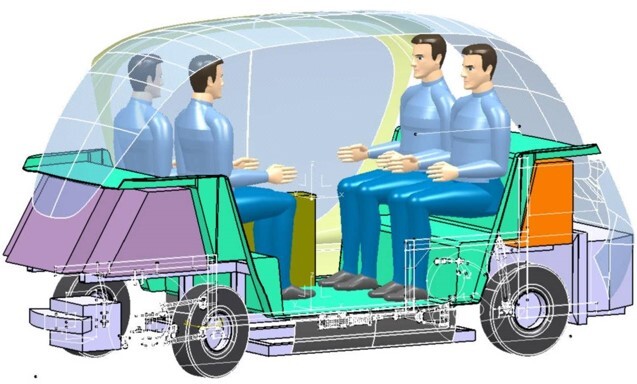

- Concept Simulations

- Structural optimization through FEA

- Product Engineering – Manufacturing feasible Products

- Functional Mock-up refinement and performance evaluation

- Models for design tests

- Pre-Product Phase – Products envisioned for mass manufacturing

- Material mold prototype for low volume production

- Prototypes for technical publications

- Physical prototypes with assembly components

- Manufacturing Support – Design verified products

- Mock-up for Product Analysis

- Prototype for regulatory approvals

- Materials testing services

Customer Benefits:

We believe that every designer should be able to execute fast and frequent revisions for their designs. Products should not be limited by technology or material availability. We design prototypes to physically test and evaluate the design concept from a fit, form, and function standpoint. From customer perspective, working with DEP to bring CAD files and design ideas to life in form of real physical models provides below advantages:

- Simultaneous Product Performance Simulation

- Engineering support for Product design

- Product Refinement with Concept Modeling and Design Verification

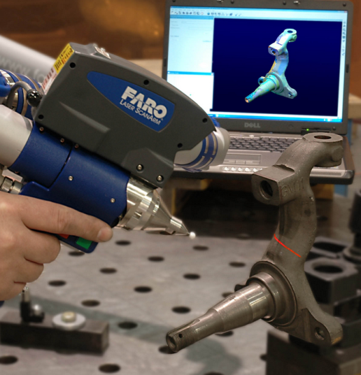

- Reverse Engineering support with 3D Scanning

- Time and money savings by optimizing design and minimizing overall costs