DEP’s Exclusive Electrification module

The development of electric vehicles has recently been a hot topic, and major industry players are accelerating their product development cycles by coming up with cutting-edge ideas for electric, connected, autonomous, and shared mobility. One way to speed up the process of developing electric vehicles is by utilizing the Electrification module (eMOD), a unique set of tools developed by DEP.

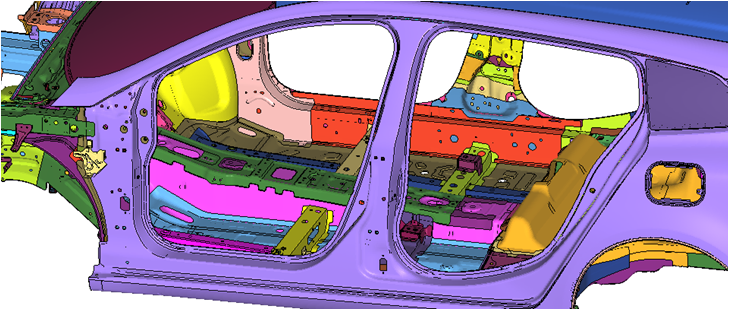

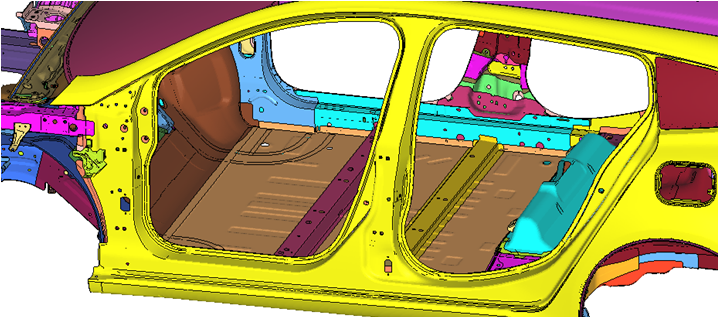

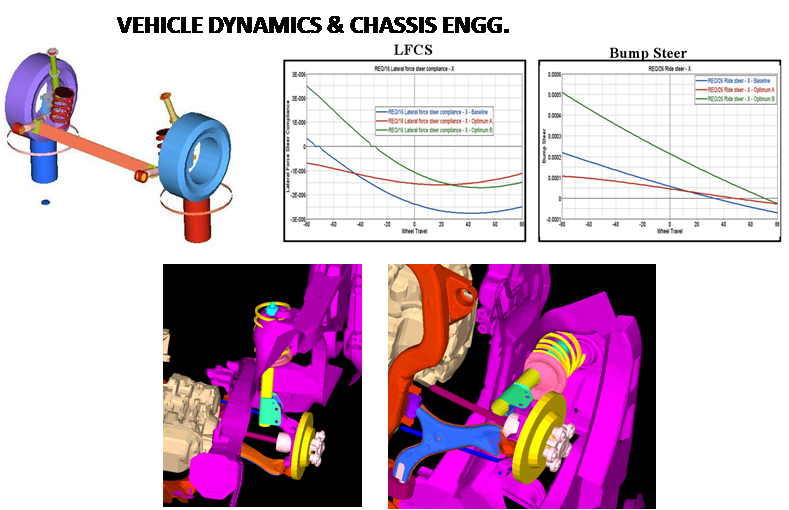

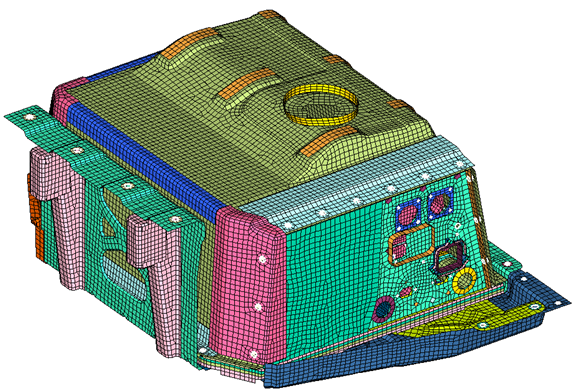

The eMOD is a comprehensive set of specialized tools used for modeling all components of an electric vehicle, from system analysis to component analysis. It consists of three layers, each with unique capabilities to support the development of electric vehicles. The foundation layer, the first layer, includes specialized meshing and model assembly tools that enable meshing for E-Propulsion units and vehicle sub-systems, both structures and computational fluid dynamics (CFD), including Battery Drive Unit, Inverters, and E-Vehicle Structures.

The second mid-layer comprises a collection of couplers, which are specialized connectors that enable the connectivity between different solvers used in electrification analysis. The final layer, the workflow layer, guides the user with computer-aided engineering (CAE) workflows for Electrification CAE analysis. These features, combined with a specialized workflow, make it possible to rapidly create Electrification CAE models and parametrize them for structural and CFD analysis, leading to faster optimization cycles.

Comprehensive Structural and CFD modeling tools available in MeshWorks:

- Battery Models

- Power Electronics Models

- Electric Drive Unit Models

- Full Vehicle Models

Key eMOD Features:

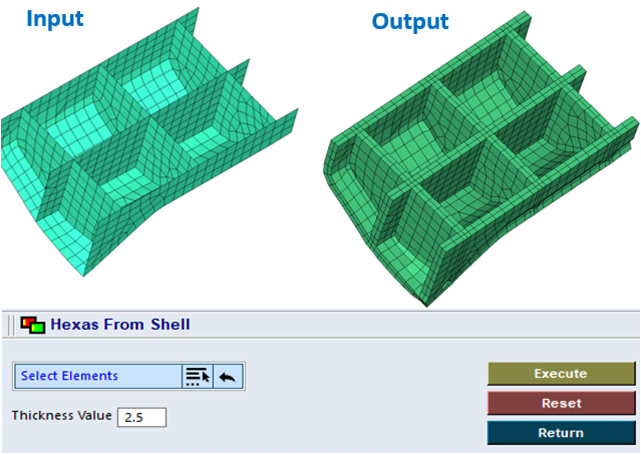

- eMOD includes specialized meshing tools for the battery, EDU, and inverters of electric vehicles. These tools offer a variety of meshing options, such as cell level, module level, and pack level meshing, making the tool useful for disciplines like crash, NVH, and durability.

- The toolset also offers specialized assembly and connection tools that enable users to quickly and efficiently create assembly connections between EV components, such as bolt connections and contact between cells.

- The models created in eMOD are parametric, which means they can be easily modified and optimized for electrified powertrain components.

- Variational and robustness studies can be conducted using MeshWorks in combination with eMOD.

- Customized ConceptWorks functions can convert a conventional ICE vehicle CAE model to an EV model in just one week using eMOD.

- The eMOD coupler utility automatically converts the output model from one solver to the input model for another solver, which is particularly useful for electrification models, such as electromagnetism from Maxwell to vibration in Nastran.

- One of the major differentiators of eMOD is its in-built electrification workflows that are ready-to-use.

Benefits of electrification module:

Fast modeling

This exclusive collection of features provides our clients with a quicker and more straightforward approach to modeling their components, resulting in saved time and improved efficiency. There is no need to undergo the time-consuming process of learning all of the modules, making it a highly advantageous tool.

Pre-defined Workflows

Our guided workflows can reduce the need for several years of experience by leading users step-by-step through the process, which involves multiple solvers. Following each analytical path is crucial in determining a component’s functional efficiency.

Unique set of tools.

Our customers can utilize our unique set of tools, including “ConceptWorks,” to create distinct structures and modify their models effortlessly. With just a few user inputs, ConceptWorks enables users to rapidly build CAE models that consist of members, bracing, and joints.

- The eMOD tool provides a significant advantage for users by optimizing the weight and aerodynamic parameters of Electric Vehicles, resulting in increased range. This is made possible through the generation of parametric EV CAE models using eMOD.

- Through eMOD’s parametric optimization capabilities, users can achieve improved performance in areas such as eMotor performance and high frequency noise reduction.

- The parametric CAE models generated by eMOD, including full battery pack assemblies with automatic stack-up adjustment, enable robust optimization that takes into account dimensional variation.

- The ‘Ready-to-use’ Electrification CAE Workflows included in eMOD significantly reduce the learning curve for new users.

- The development cycle time for Electric Vehicles can be reduced by over 30% through virtual CAE engineering with eMOD.

Electrification workflows facilitated by MeshWorks

- Electro-Magnetism Analysis (EMA) of Electric Drive Unit

- CFD and CHT Analysis of Electric Drive Unit

- High Frequency Noise Analysis of Electric Drive Unit

- Vibration and Shock Analysis of Inverter

- Vehicle Level Crash Analysis for Battery Pack

- System Modeling of Electric Vehicle

- Optimization to minimize Aero-drag

How does it compare to other similar software?

| Feature | MeshWorks – eMOD | Similar softwares |

| Customized Meshing and Assembly Tools for Electrification | ✔️ | ❌ |

| Ready-to-Use CAE Workflows for EV Analysis | ✔️ | ❌ |

| Parametric CAE Technology for Electrification | Unmatched | Varies |

| Coupler Technology for Connecting Multiple Solvers Used in Electrification Analysis | Exclusive | Varies |