In this webinar, we are focusing on custom tailored toolsets that enables optimization at system and sub-system level. We are showcasing how to create parametric FE models, ConceptWorks tools, CAD morphing tools that provide critical inputs to engineers helping in packaging studies, manufacturing considerations and deliver the necessary heads up to partners/ suppliers/ vendors.

View Recording

This webinar focuses on Mesh Modeling and Assembly tools in MeshWorks that will cover battery modeling and connection tools, Rotor, Stator and Housing modeling related to Motors considering NVH and Durability performance assessment. Demonstrations would cover time savers to model and assemble complex battery system components, electric motors and transmission systems besides that engine that is part of hybrid architectures.

View Recording

Simulation and analysis can help you design the ideal configuration of a turbine blade, store nuclear fuel safe and secure, pick the best alloys for a gas/steam combined cycle plant, generate electricity from wave power cost-effectively, etc. MeshWorks from DEP presented as part of this webinar addresses how we can develop design validations using CAE.

View Recording

A comprehensive tool set that can handle all complexity from virtual validation model build and design engineering perspective would make a big difference.This webinar focuses on MeshWorks enabling Design and Virtual Validation (CAE) workflows for Farm and Construction Equipment industry.

View Recording

As we start our journey into Industry 5.0, we are facing increasing focus on mass customization in some product lines, Digital Twin supporting design exploration beyond optimization, Simulation methods to support V Cycle with ability to operate on RT (Real-Time) and Data model-based design advisor. This is where MeshWorks PA process scores with its ability to translate steps into code. Together with Design Exploration architecture MeshWorks PA can deal with both ROM and Detailed Model builds. This webinar mainly focuses on unique process automation architecture.

View Recording

This webinar focuses on Mesh Modeling and Assembly tools in MeshWorks that will help build plastic mesh models for systems / sub systems from automotive, aerospace, bio medical and consumer goods domains. Demonstrations would cover time savers to model and assemble door trim, seat trim, face mask / respirator and dryer.

View Recording

This webinar focuses on Integrated and Associative modeling tools in MeshWorks will cover how MeshWorks can help you save time and effort. Both Integrated and Associative Modeling tools are applicable for automotive, aerospace and heavy engineering domains CAE users handling sheet metal and cast parts assemblies.

View Recording

This webinar focuses on class leading custom tool sets in MeshWorks that enable CAE data morphing at complete system level and sub system level. ConceptWorks tools in MeshWorks are state-of-art tools that help convert input from topology into valid structural load path thus saving time.

View Recording

Virtual Validation and parametric FEA model is very important for optimizing stent design towards balancing various performance metrics like wall stress, radial recoil, foreshortening and radial strength. This webinar addresses the high quality model creation for Virtual Validation for stent.

View Recording

This webinar focuses on Integrated and Associative modeling tools in MeshWorks will cover how MeshWorks can help you save time and effort. Both Integrated and Associative Modeling tools are applicable for automotive, aerospace and heavy engineering domains CAE users handling sheet metal and cast parts assemblies.

View Recording

This webinar focuses on post processing tools in MeshWorks will cover how Hot Spot Extractor, Score Card Utility tools in MeshWorks can help you save time and effort. Both Curve and Fringe/Contour plotting tools in MeshWorks are applicable for automotive, aerospace and heavy engineering domains CAE users handling sheet metal and cast parts assemblies.

View Recording

This webinar focuses on model assembly tools in MeshWorks, regular and special connection options and will cover how MeshWorks can help you save time and effort with process automation. Model assembly tools demonstrated would cover multi disciplinary application areas like Crash, NVH and Durability. Conversion of connection formats and types while converting models across disciplines would be demonstrated.

View Recording

Reduction of skin mesh modeling time for CFD as applied to exterior flows (Aero), internal flows besides being able to do have parametric mesh is always good advantage to have. Wetted surface extraction also helps the user while building grids for CFD calculation. Morphing is great way to realize shape changes for what if scenarios and at times it is not convenient to do it at mesh level. With CAD morphing in MW it is possible to morph CAD directly and generate mesh using automation. Thus MeshWorks influences Aero/Thermal modeling positively by adding efficiency tools.

View Recording

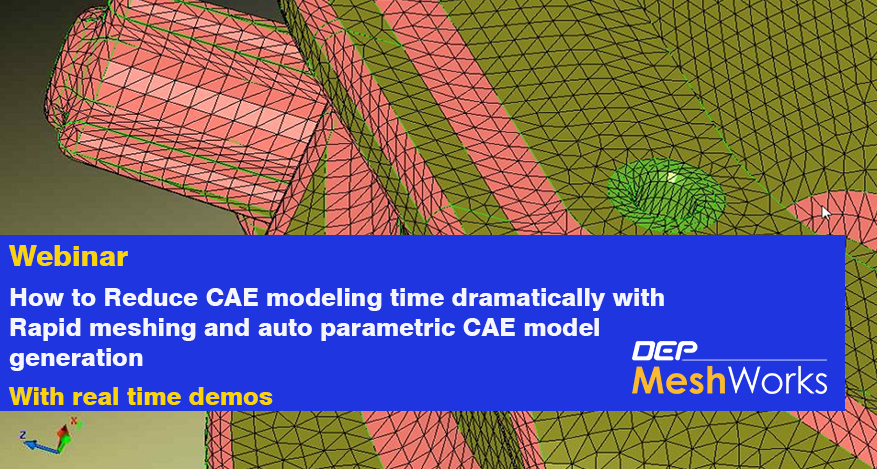

Reducing CAE modeling times is the need of the day, and the design teams are under tremendous pressure as manufacturers are trying to get newer products to the market faster. With the latest in MeshWorks 8, there are an impressive set of tools which work together with your existing tools and processes to reduce CAE modeling time drastically. With DEP MeshWorks, you get a single integrated pre-post processor, essentially eliminating the need of shuffling across multiple software, which can save you upto 30% of your time.

View Recording

Learn through live demonstrations about unique meshing methods for complex plastic parts involving ribs and specialized features such as heat stakes, dog houses, bosses, etc. Typical components demonstrated would be door trim, IP substrate, floor console, pillar trims beside fascia, grills, head lamps and thin walled castings. You will see tools that help with tasks such as automatic thickness assignment and rib insertion for plastic parts. You can also view the utility of tasks like mesh stitching options for plastic attachments via live demos.

View Recording

This webinar focuses on post processing tools in MeshWorks will cover how Hot Spot Extractor, Score Card Utility tools in MeshWorks can help you save time and effort. Both Curve and Fringe/Contour plotting tools in MeshWorks are applicable for automotive, aerospace and heavy engineering domains CAE users handling sheet metal and cast parts assemblies.

View Recording

Ready to use CAE: Manually creating geometry, mesh or connections takes a significant amount of time for a design engineer to do. DEP MeshWorks has a powerful Design Enablers module that will allow users to automatically create typical design solutions required to improve structural and CFD performance and reduce weight. These Design Enablers can be executed as an integrated solution complete with properties, materials, connectors etc. The Design Enablers can be executed as a single instance or as a parameter with multiple instances.

View Recording

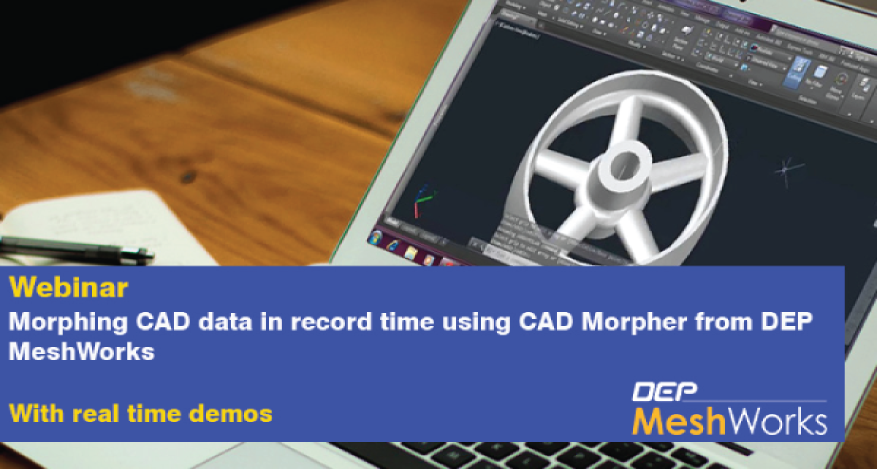

During major design changes, a source of major time consumption is the time taken between the CAE teams and the design department. CAD Morphing can significantly reduce the CAD data generation time since the data can be fed from available existing donor CAD Data, and the Optimized Finite Element and CFD data can be communicated to the design department directly as morphed CAD data. This webinar will demonstrate how MeshWorks CAD Morpher can aid in rapid CAD morphing.

View Recording