Analytical technique development is a persistent and interdependent process connected with the departments of R&D, quality control, and quality assurance. The robustness of methods should be considered throughout the early phases of method development because quality of the data ultimately helps to decide which method will be authorized. Analytical processes are crucial in the assessment and management of equivalence and risk. It aids in the development of product-specific acceptance criteria and seamless outputs having higher quality. Combining analytical and experimental methods in the upfront design and development stage has become a critical tool to cut down the product development and process time.

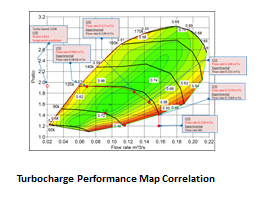

For various complex mobility systems, DEP developed reliable physics-based 1D and 3D CAE models. CAE models, as well as real-time experiment calibration and simulation correlation, are also developed as part of this project.

DEP Value Addition:

- Data collation for a specific analytical problem from various sources.

- Establishing accurate sensitivity parameters.

- Explicit analyzing of factors affecting accuracy.

- Performing specific Range of analysis required for the studies.

- Maintaining precision data at all stages.

- Analyzing consistency and durability throughout the development.

DEP Analytical Method Development services includes:

- Performance Correlation Analysis

- CFD Analysis – mainly focusing on Combustion Procedures.

- CAE evaluation of Automobile at System and Component level.

- Complete CAD data management and co-ordination on CAD Model build.

- Targets Evaluation – vehicle level, system level, component level, etc.

Customer Benefits:

- Reduce any risk to the future resilience of the method.

- Price optimization

- Derive model for Visual environment rendering