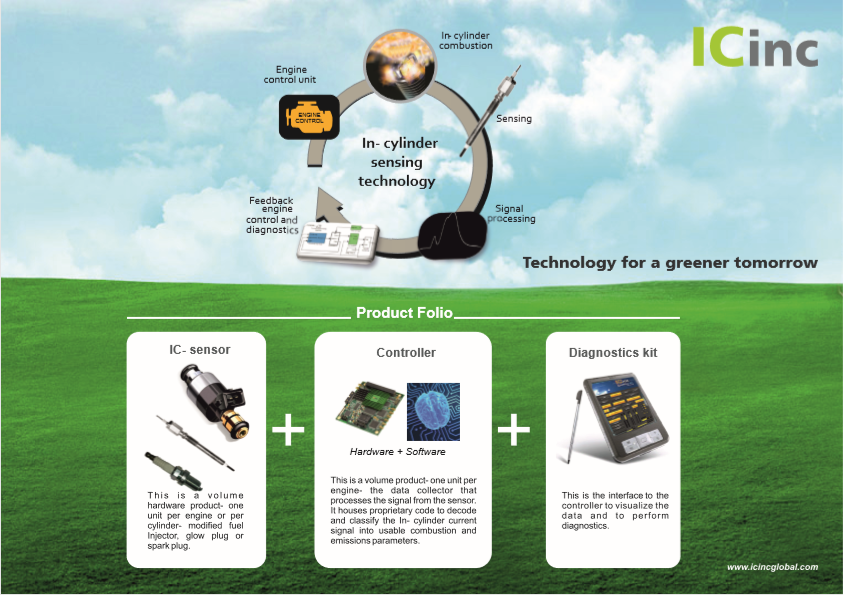

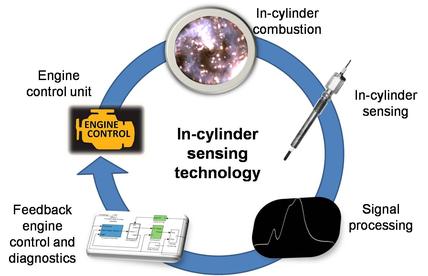

The automotive industry is one of the most competitive in which organizations compete by differentiating themselves based on style, utility, price, technology and many niche features. The one feature that the majority of car buyers would agree as most important is fuel economy. In today’s manufacturing world, automobiles are required to meet stringent emission standards in addition to internal targets for fuel economy and performance in order to stay competitive. With the need to reduce humanity’s environmental footprint increasing on daily basis, DEP has developed new capability for real time in-cylinder sensing. This IC Engine sensor technology helps improve the efficiency and reduce emission of internal combustion engine. An advanced in-cylinder combustion sensor complemented with our proprietary advanced algorithms has the potential to replace pressure sensors, oxygen sensors and knock sensors. The latest technology from DEP enables performing multiple sensing tasks and real time Engine management by providing feedback to the electronic control of engine to achieve goals of future stringent emission norms and fuel economy standards.

For automakers, designing a brand-new engine is far from the path of least resistance. A better approach would be to monitor the combustion activity to see where improvements can be made. Many techniques have been investigated to directly or indirectly monitor the combustion process including:

- Crank shaft dynamics to detect misfiring, found to fail in multi-cylinder engines and at high engine speeds

- Optical sensors, found to lack accuracy and durability

- Techniques based on Neural analysis, found to be limited to certain operating windows, beyond which they are not accurate

- Pressure transducers

- Advanced sensors

Based on these techniques, the engineering expert team at DEP come up with in-cylinder combustion sensor which will give real time feedback to the engine’s electronic controller.

IC Sensor Advantages

- IC sensors are superior to pressure transducers as they can predict combustion, performance and engine out emissions in addition to their low cost

- The advanced IC sensors with our new IP algorithms have the ability to produce basic information about engine combustion, performance, and emissions parameters on a cylinder-to-cylinder, and a cycle-by-cycle basis

- These unique abilities are necessary to control and fine tune the production engine to meet its targets over its life time

- With IC sensors, the above can be achieved without the need for drilling another hole in the cylinder head by adapting the fuel injector or spark plug or glow plug as the ion sensor

The product is the result of collaboration of DEP and an academic institution who developed the IP and is allowing DEP to help its vision reach the markets. The IC sensor has applications in low volume areas such as racing industries and developmental engines, high volume areas like two and four wheelers, across global auto sector. The major advantage of this project is providing a disruptive technology that will help build a world with fewer emissions by achieving greater fuel economy.