CAE Software (CAE – Computer aided engineering)

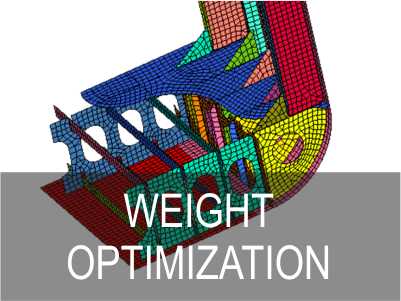

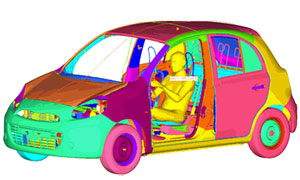

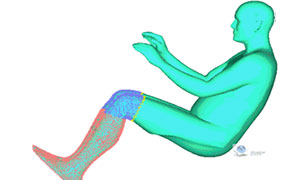

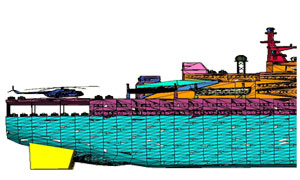

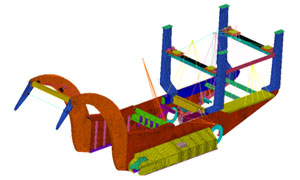

CAE software or simulation software helps stimulate performance in order to assist in the resolution of various engineering problems or improve product designs across various industries including Automotive, Medical devices, Construction equipment, Aerospace and Defense. It covers computational fluid dynamics (CFD), multi-body dynamics (MDB), finite element analysis (FEA) and optimization capabilities. By doing so, CAE software enables users to optimize, stimulate and validate processes, manufacturing tools and products.

DEP (Detroit Engineered Products) provides CAE software, which is used across industries in India and USA to help you reduce product development costs and time by enabling the creation of conceptual drawings of the products which performs well on every parameter of stress durability and fatigue. CAE software can provide support to your business. This goal is achieved by the usage of reference architectures which are capable of placing information views on business processes. The features which characterize DEP (Detroit Engineered Products) software solutions is their ability to run intensely computed studies much effectively on powerful computing platforms.

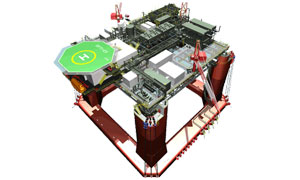

CAE software allows businesses in India and USA to gain expertise over performing complex analyses from a wide choice of services including stress durability and fatigue while applying real-world experience to multiple industries, including autonomous vehicle, commercial truck, entertainment, aerospace, oil and gas, and consumer product.

The benefits of DEP (Detroit Engineered Products) provided CAE software solutions:

- Integrated process management and CAE data help your business to improve designs to a broader community by effectively leveraging performance insights.

- Allows you to analyze components and products for Stress durability and fatigue using Finite Element Analysis (FEA)

- Help in cost reductive as CAE softwares can provide performance insights in the early stages of product development when the design changes are less costly to make.

- Allows Product designs to be evaluated and redefined using computer simulations rather than time and money consuming prototype testing.

CAE software allows businesses to reach their end goals of confidently identify acceptable or superior materials and designs for each unique product. Through Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD), which are collectively known as CAE, helps you achieve these goals at a lower cost and in less time than traditional prototyping.