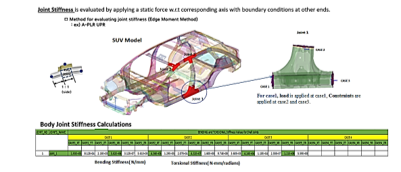

Reduced order modeling is an approach that combines concepts from data science, modeling, and simulation as a means of lowering the computational cost of models while maintaining high levels of realism in significant system components. It is considered an effective approach that enables real-time analysis and lessens the computing strain brought on by high-dimensional uncertainty quantification (UQ) problems. Because of market demands for shorter design cycles that produce higher-quality products, ROM processes have grown in popularity in the product development industry. DEP’s highly automated Reduced Order Modeling techniques promote simplified model updating processes, which in turn drastically reduce the run-time, accelerated by fast design iterations.

ROM Building and Optimization Tool Kit from MeshWorks:

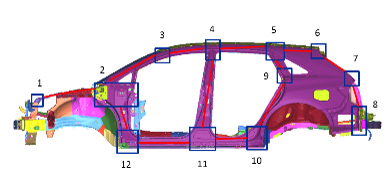

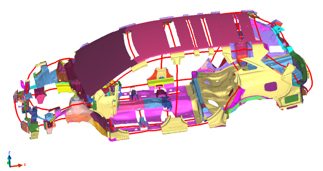

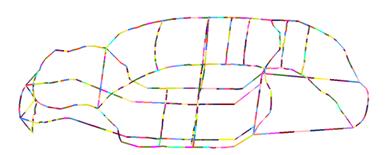

- Highly automated 3D-to-1D beam creation.

- Highly automated joint creation: a) beam, b) spring.

- Auto-parametrization of ROM models.

- Designer Tool using ROM Models.

- Highly automated Topo Iso surface-to-beam models.

- Section synthesizer for non-linear load cases.

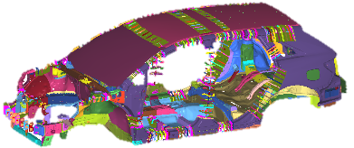

- Automated 1D to 3D member creation (sections to members).

- Joining members to create joints.

- ConceptWorks applications for: Topo Iso-surface to Concept Shell model.

ROM Approach: Advantages of Using MeshWorks:

- Automated conversion of complex 3D models to beams.

- Drastic reduction of analysis run-time without compromising the detailed model build.

- Lots of design iteration at a rapid rate and subsequent optimization at lightning speed.

- ROM build and update duration is between 1 to 3 days, based on the level of complexity.

- Eliminates the tedious design cycle of remeshing, morphing, and CAD update for 3D models.

- The CAE team can benefit from the auto-parameterization and optimization options for the complete family of ROMs and cross-sections to create concept models.

- Section synthesizers are available for all 20 standard section elements to study various load cases.

- ROM builds are parametrized for fast optimization and create equivalent standard manufacturable sections.

- 1D optimized cross section to 3D FE and CAD Model conversion with less effort and in reduced time.

- At an early stage of vehicle development, the design team can focus on customizing models for performance and lightweighting.

Uniqueness of MeshWorks:

- Back-and-forth convertion of detailed model to beams & springs and then back to detailed model after analysis in a rapid time frame – 3D to 1D

- Automatic topological identification of tubular & joint regions and appropriate ROM modeling for those regions

- Auto-Parametrization (linear & non-linear) of ROM models enabling Fast Optimization

- Auto conversion of optimized ROM to 3D models through ConceptWorks – 1D to 3D