Today’s modern manufacturers demand more optimized and customer satisfying models to be made out of their workshops in less time. More designs have to be explored and each design have to full fill certain constraints before moving to the production desk. With the above mentioned critical requirements every manufacturer is on the look-out for a best tool that makes both ends meet. CAD Morpher comes as a saviour for the day with the ground-breaking concept of building CAD models faster than ever imagined before time duration. Its ability to handle both CAD and CAE models makes it a perfect link between CAE and Design teams. Optimized Finite Element and CAD data can be communicated to the design department directly as morphed CAD data which is extremely useful in creating multiple designs with various specs and constraints in lesser time.

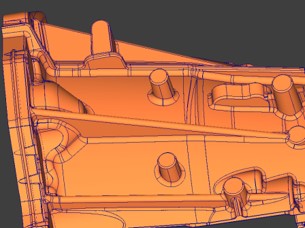

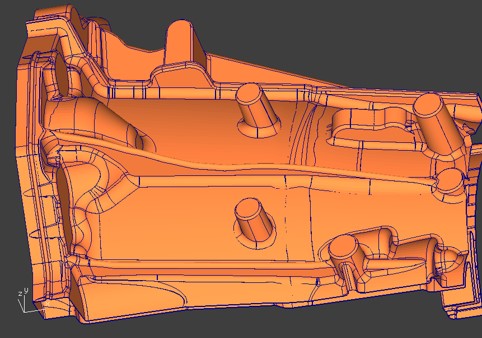

The CAD-Morphing is a transformational feature of MeshWorks which provides users the ability to efficiently modify any existing CAD data of a product directly to new shapes. For example, the complete BIW CAD data of an existing production vehicle can be made to morph and fit a new vehicle’s styling data and/or proportions. This is possible for all auto parts like Body structures, Powertrain, Chassis, etc. Several months of CAD development can be reduced using our patented CAD morphing technology.

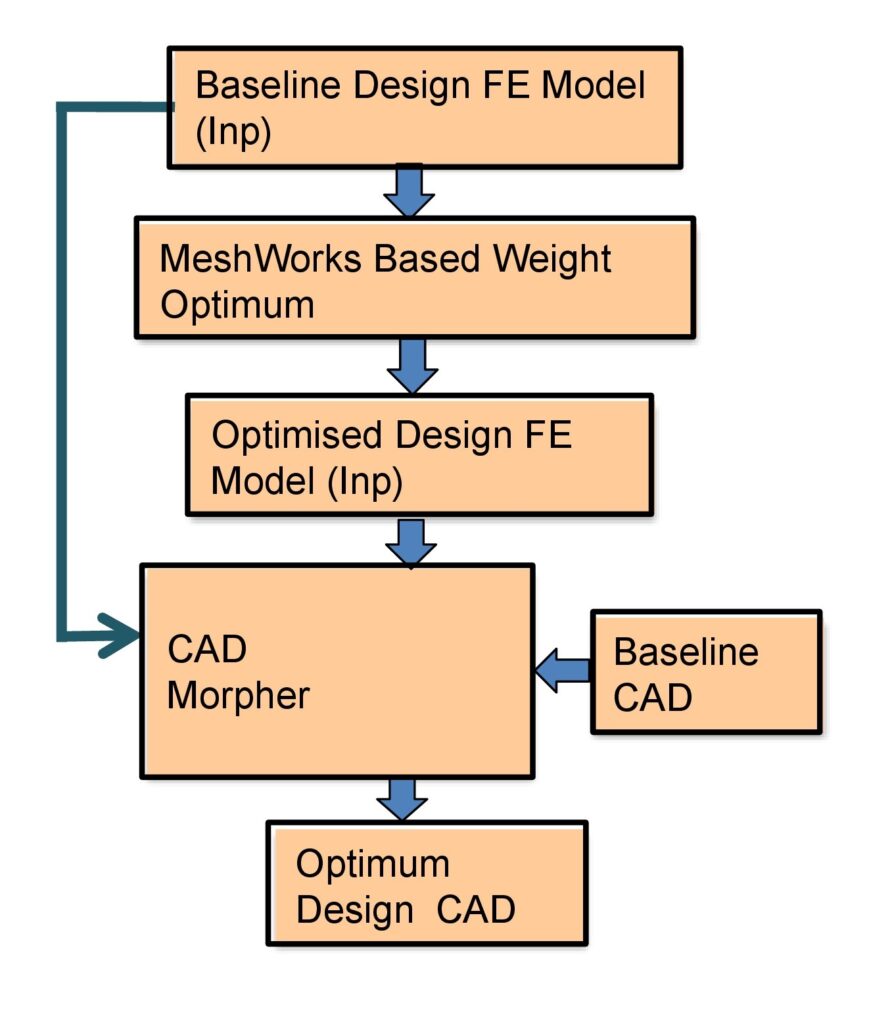

How CAD Morphing Works:

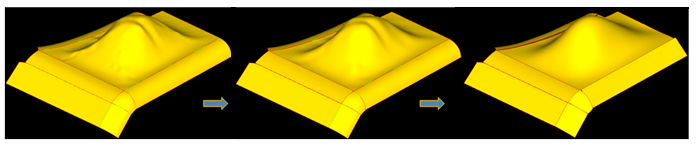

STEP 1: Recording of CAE morphing steps- Entire morphing history of the CAE models are saved.

- Appropriate sequences are remembered and saved.

- CAE resolution modified to CAD resolution.

- The morphing history is applied step by step on every part of the original CAD data.

- Morphed CAD data is evaluated for quality after each morphing step.

- Resolution parameters are adjusted to achieve the best quality.

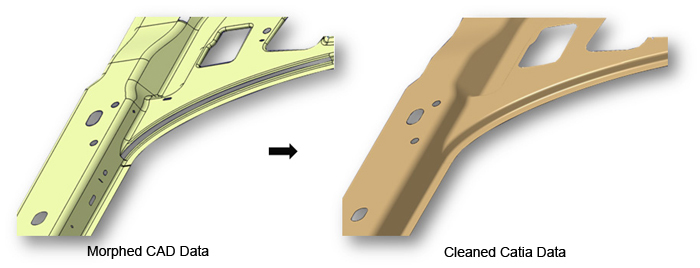

- Our engineers have developed a well-defined process for converting morphed surface data (in IGES format) into native format (CATIA).

- This involves a sequential process of CATIA operations that the CAD designer will execute by using a particular method.

- The resulting element of CAD geometry will be of production quality.

Functions and Applications:

CAD Morphing enables early availability of reference CAD during early engineering stage unlike the traditional CAD process which is a reactive process and lags behind the development cycle for any product. Some of the notable features of MeshWorks CAD Morphing are:

- Its capability to morph CAD data in a wide variety of scenarios very easily, efficiently and rapidly.

- Delivering optimized and balanced products faster to market.

- Implementation of CAD Morphing in various stages of vehicle development including:

A) Early concept stage: Old vehicle CAD data can be fitted to target new styling data and vehicle proportions

B) Vehicle architecture development: Existing BIW CAD data can be automatically updated to fit new sections as determined by architecture team

C) Vehicle optimization: Existing vehicle CAD data can be updated to match optimized results obtained by the CAE team

Major application area of CAD Morphing are:

- Packaging:

- Human factors

- Criteria evaluation

- Vision Study

- Typical Section Development & start data for detailed CAD

- Early Formability & weld access study

- Zone and Limits compliance

- Evaluate Styling theme impact

Benefits:

With this ‘game-changing’ CAD Morphing functionality of MeshWorks, customers can build models up to 10 times faster than the conventional methods. Ultimately CAD Morpher is promising a drastic reduction in the product development cycle time.

With CAD Morphing enabled Product Development, customers achieve:

- Rapidly Develop new vehicle derivative of existing platform

- Maximize carry over part and process

- Confirm performance compliance at design stage

- Provide complete new CAD reference data

- Ultimately, saving a huge time in Product Development