When it comes to engineering, a good design is critical to creating a successful product. However, engineers often face complex design scenarios that can challenge the quality of their work. Making machinery with custom configurations demands precision and exploring a variety of variations and combinations. To satisfy the unique specifications of every product iteration, optimized design management is essential. But making design decisions at the end of the product cycle can be costly and increase the time-to-market duration.

To address these challenges, engineers need a time and cost balanced approach that maintains high standards and ease of manufacturing. This is where process automation comes in. MeshWorks is a tailor-fit design management application that combines various engineering concepts to help designers with quick and easy solutions during the early stages of product development.

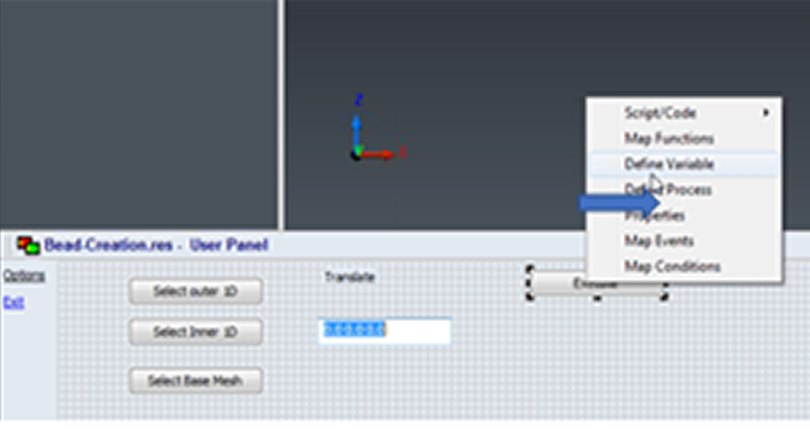

One of MeshWorks’ key features is the ability to customize functions and automate redundant procedures, resulting in significant time savings. Using a fast Record > Create- GUI > Plumb > Publish process, engineers can rapidly automate CAE functions without requiring scripting or programming expertise. This includes processes such as CAD, Meshing, Model Assembly, Morphing, Parametrization, and Post-processing. Once these processes are published, they can be shared with all users in the organization as a simple resource file, without requiring any new software releases.

In addition to these features, MeshWorks also allows for the integration of external exes and scripts (Python, Java, etc.) into the automation process, providing even greater flexibility and functionality. With MeshWorks, engineers can streamline their design management processes and focus on what really matters – creating high-quality products that meet the unique specifications of their customers.

Uniqueness of MeshWorks:

- The PA creation is a simple recording of the entire process with ‘on/off ‘recording options in MW. The entire recording automatically becomes the process and the data in the recording will become associated variables for the PA function.

- The GUI creation can be done as the result of simple drag & drop actions done by the user and it doesn’t need scripting in backend).

- The linking of the backend process to the frontend user interface is done by ‘Drag & drop’ making it a quick/easy function interface creation method.

- The MW PA is created with in-built flexibility to connect/integrate with external scripts like python and similarly MW PA’s can be called from within external environment like TCL/TK (There is complete generality applicable PA functions).

- A robust count of 60 Specialized Pre-packaged PAs are available in MW23 that acts as Enabler Functions for user’s tasks.

Functions:

- Repetitive CAE processes can be rapidly automated using a fast Record > Create-GUI >Plumb > Publish process using MW Process Automation function.

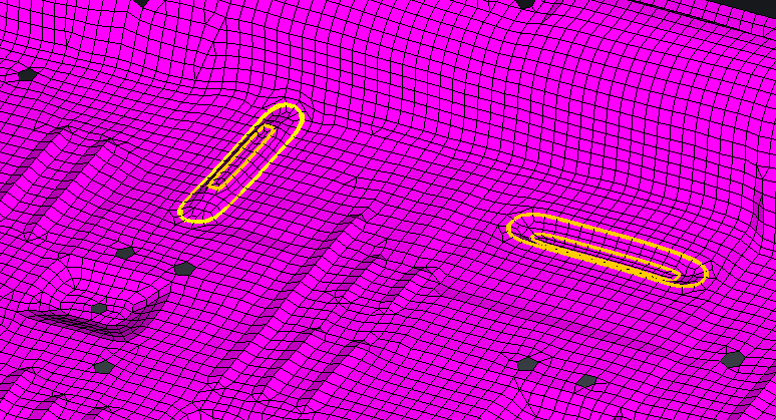

- Very complicated geometry and mesh creation processes can be automated with virtually no scripting or programming expertise.

- The process automation can be performed in as simple of way as just a ‘drag & drop’ action to create GUI and plumb it to the recorded process.

- It is model-independent and enabled with automatic conversion of recorded process to a data flow chart which can be plumbed to user-defined GUI.

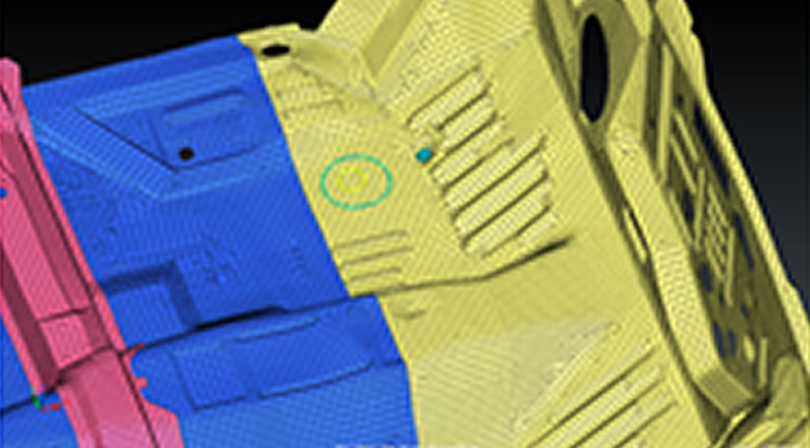

- Processes that could be automated include a) CAD, b) Meshing, c) Model Assembly, d)Morphing, e) Parameterization, f) Post-processing etc.,

Key Parametric Automation features:

- In MeshWorks, the creation of Parametric Automation involves a simple recording of the entire process with options to turn recording on or off. The recording is automatically converted into a process, and the data in the recording becomes associated variables for the PA function.

- The user can easily create the GUI by performing simple drag-and-drop actions, without the need for scripting in the backend.

- Linking the backend process to the frontend user interface is a quick and easy process accomplished through drag-and-drop, allowing for fast function interface creation.

- The MeshWorks Parametric Automation is designed with built-in flexibility to connect and integrate with external scripts, such as Python. Similarly, MeshWorks PA’s can be called from within external environments like TCL/TK, making Parametric Automation functions completely generalizable.

- MeshWorks offers a robust selection of 60 specialized pre-packaged Parametric Automations, which act as enabler functions for users’ tasks.

Benefits:

- The specialized PA’s that are available in MW23 help users save a lot of time.

- The PA function in MW is a visual & easy method to create PA where no scripting knowledge is required which in-turn reduces the time used in the PA creation process.

- Many of the ‘specific’ needs of users are taken care of using the pre-packages PAs.

- With this institutionalized PA process, customers can keep the required proprietary functions in-house, with no need for sharing.

- Processes can be standardized across the entire organization.

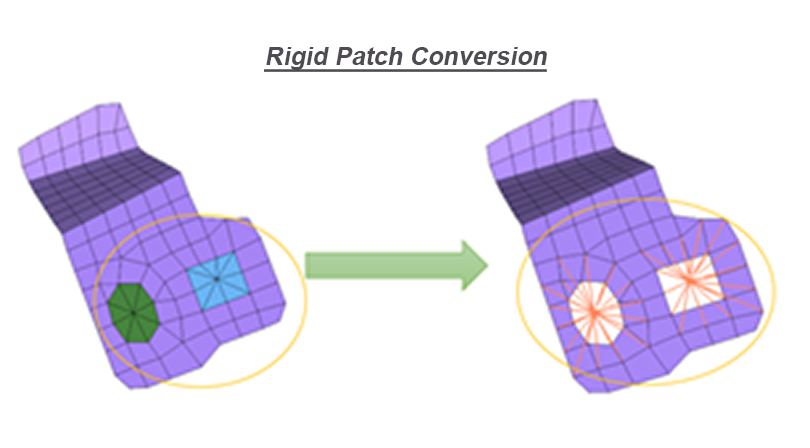

- Manipulations possible at CAD/CAE geometry level.

Typical Processes That Can Be Automated:

- CAD geometry creation and manipulation.

- Complex meshing & assembly.

- Load case set-up, results recovery & auto report.

- Automated parametrization Etc.