New Product: Design, Engineering & Success Trends

Global market dynamics, combined with increased customer expectations, are transforming the product development requirements in this highly interconnected world. The usual challenges of cost efficiency, reduced time-to-market, quality and response to scaling, pressurizes the manufacturing process. But the manufacturers are now turning towards technological innovations as a solution to excel & position themselves as market leaders. These methodologies mark a convergence point for time-to-market and time-to-profit.

Product Engineering Phases:

Starting from development, and optimizing to enhancing, each product development cycle passes through various engineering phases. The entire realization cycle when following a refined path helps achieve the edge in quality, functionality, reliability, and lifespan consistency. The systematic approach in any product engineering process follows the below steps:

1.Idea conceptualization

A clear concept statement is needed to effectively manage product design throughout the development cycle. The designers and product engineers, when provided with defined goals, can prepare the strategy right, from ideation and prototyping to delivering end-to-end products.

Engineering Importance:

Consultation and proper research to validate a product’s market fit and prioritize the features are extremely important for expected and augmented requirements for a product. With a validated concept, there is an advantage to justifying the practicality of the concept before investing in any resources.

2.Design Creation

The product engineers begin creating innovative designs for the product using the finalized elements of the first phase. This phase provides a great opportunity for improvement, specifically on the durability and reliability criteria. There is a systematic verification done for all agreed features towards the visualized product.

Engineering Importance:

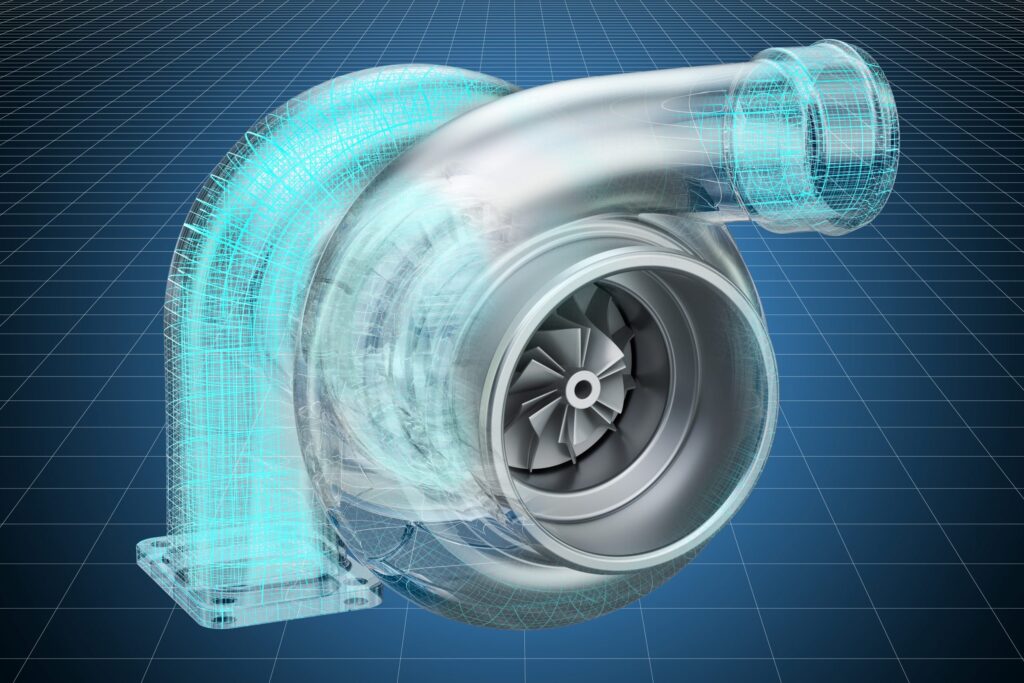

The demand to develop a new system/product faces the challenges of agility, robustness and cost-effectiveness. A detailed assessment is made to ensure that the ideas are good and will satisfy customers. Implementing CAE for virtual validation at early stages to do verification and correlation increases the reliance of the product. Design optimization done using CAE techniques factors in the feasible solutions indispensably. It also helps seamlessly integrate core ideas with quality.

3. Product Development

To validate all the hypotheses of the design, the product engineering team commences this stage by manufacturing a hardware/digital prototype that facilitates testing. Here the product is developed based on the design phase inputs, with regular back-end checks made throughout the process to assess and mitigate the “risk of failure” for the end-user and the project itself.

Engineering Importance:

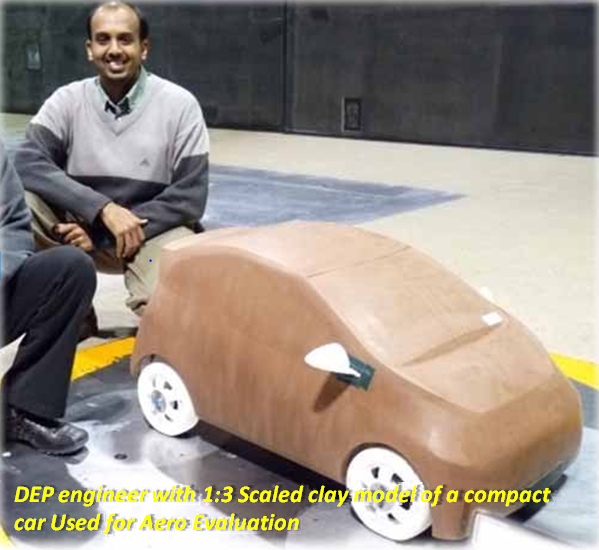

Functional implementation of parametric variations in a simulated environment is carried out to validate the product according to use-case scenarios in virtual test mode. Using computer-aided simulation, engineers now have a significant potential to gather intelligence and implement appropriate parametric changes to products prior to their being released for manufacture and onto the market. Upon completion of virtual optimization, the prototypes are developed to check adherence to physical stature. With advanced simulation, there is now an open, continuous, and interoperable data flow to iterate designs and help enhance the next generation of products.

4. Testing:

Using the defined set of technical specifications, deadlines, responsibilities, and budgets for the developed product, the product engineers now employ various testing procedures. The product is subjected to stringent quality checks to ensure that it is free of flaws and can be used as intended. Before launching the product commercially, there will be troubleshooting and the removal of subpar features.

Engineering Importance:

The main objective is to avoid errors or flaws at the early stage. Modifications and rectifications are done to ensure agile manufacturing and release of products to commercialization. Robust testing is required at this phase to back the decision on large-scale production.

5. Release & Roll-Out

The final and massive cost-inclusive stage of product development is introducing the product into the market. There are various strategies deployed by the manufacturers to make the product success at this stage. During this phase, there will be mechanisms designed to gather market intelligence in the form of customer experiences and feedback that are required for the smooth running of the product lifecycle.

Engineering Importance:

The product development team begins to operationalize the manufacturing process in the best way to maximize the success rate. With the ‘Product Lifecycle Management’ stage getting initiated at this phase, subsequent enhancements will be ideated and shaped based on target reception and till another product or variant comes in to compete. With the support of advanced technology and tools, the work on the next big breakthroughs for the product begins at this step.

6. Evaluation, Maintenance & Product Re-Engineering

A continuous update for the product, from time to time, is required to make sure that it maintains the same standards. The product should be refueled with data collected using performance evaluation and support systems. Enhancements need to be done according to the latest technologies available in the market. By implementing the analysis results, the engineering team is providing sustenance for the intended lifespan of the product.

Engineering Importance:

Re-engineering holds importance because it makes the product design meet the scaling demands of the market and helps the product evolve. Ongoing product management is now part of every product development since all products need seamless upgrades and incredible customer support.

Handshake of New-Age Technology & Product Engineering:

With tremendous shifts in global market status, every product development company is facing many business challenges in product engineering while trying to focus on its core business. Architecting the entire product development spectrum from design and development to deployment needs robust technical expertise and experience. Augmented with the power of services and expertise, solution providers are enabling customers to decrease time to market, and enhance processes, quality, and yield. The best solutions and best insights are creating value as companies design, develop, test & manufacture new products. A close collaboration between engineering and product teams is the success formula to define, build, and evolve compelling, high-performing product solutions in a variety of shapes and sizes.

DEP – Product Engineering Suite:

The DEP team commences their collaboration at the stage of ‘identifying the opportunity’. We partner with the companies at the very start to support them in selecting the appropriate path for any product development. We aim to build unique, cutting-edge products that equip our customers to grow and amplify their unique value to surpass the competition on all engineering fronts.

Our product engineering support stands out in terms of the adoption of new-age technology, scaling support, and leveraging best practices across industry segments such as automotive, aerospace, semiconductor, heavy engineering, medical devices, marine, etc.

Below are some of our capabilities that span the entirety of the product development process:

- Mechanical, Electromechanical & Design Engineering

- Prototyping, Benchmarking & Roadmap support

- Testing, Verification & Validation Solutions

- Simulation & Design Optimization Solutions

- Product Lifecycle Management – Re-Engineering & Enhancements