Industry 5.0 and its impact on product development

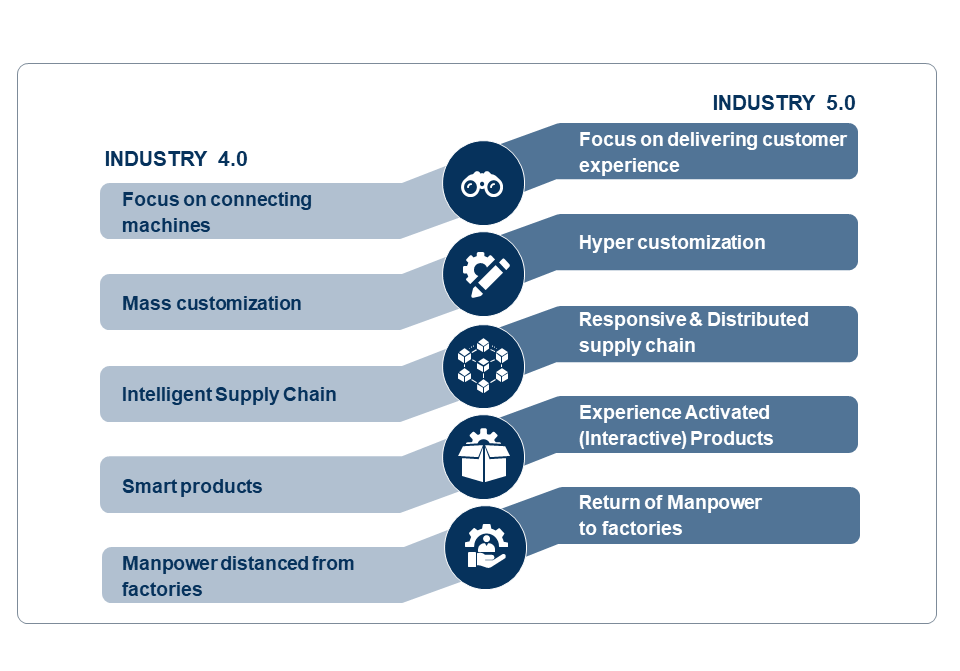

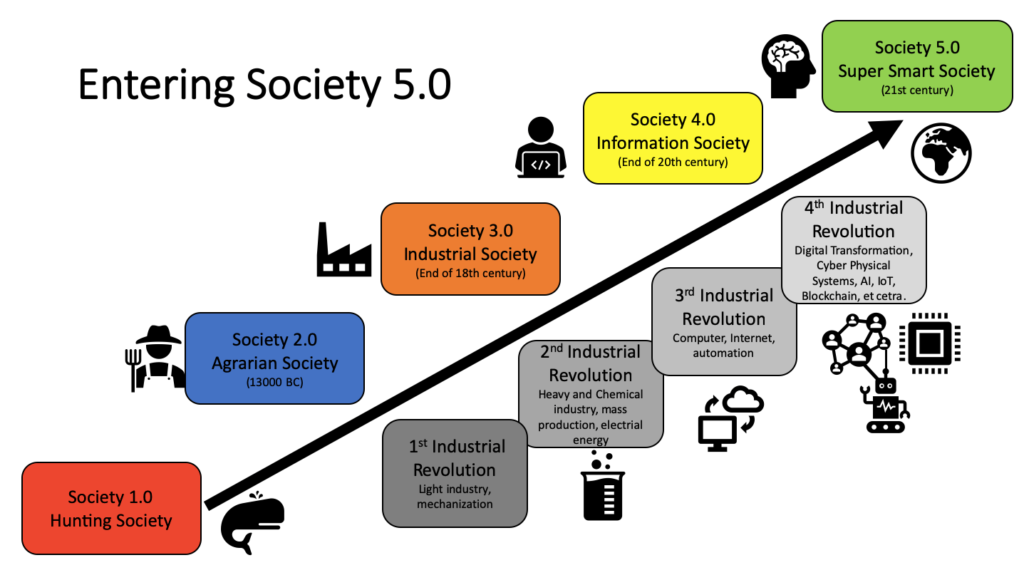

Throughout the history of manufacturing, there have been several distinct phases of production that have defined the technology of that time. Today, we are in the midst of a massive digitalization of once completely mechanical processes. Typically, manufacturing has taken on the label of “smart” through the integration of IoT, AI, Cyber-physical systems, and Cloud and cognitive computing in Industry 4.0. Adding more human touch for high-speed accuracy of industrial automation with the cognitive, critical thinking skills of humans is Industry 5.0.

Industry 5.0 can be perceived as something that empowers technology, as well as an ideology that enhances the life standards of society. At the core of Industry 5.0, are new business scenarios aided by advanced technology, focused on delivering individually tailored customer experiences. The individual definition of products, services and solutions will fuse into one and create Industry 5.0—the era of experience. By honing the interaction between humans and machines, Industry5.0 aims to give an added value to production, thereby creating personalized products which will meet customers’ requirements. We can witness the ultra-fast precision of automated technology works with a human’s critical thinking skills and creativity.

Industry 5.0 will step into the future daily business due to the velocity of further technological development and changing human process integration. On the manufacturing side Industry 5.0 means cobots in the place of robots. The Design and Engineering activities in Industry 5.0 would include and look beyond Digital twin, AR, VR, ROM and automation into collaborative automation. As we progress in this revolutionary path we have to invent methods about how we are going to optimize human efficiency and productivity as we collaborate the industrial automation with the cognitive, critical thinking skills of humans. The demand towards high degree of customization / personalization in products expected by users is bringing in exciting time for engineers, who are designing and building them with precision and speed. It’s already shifting from “we design, you buy” to “you/ your design”.

Simulation Software tools enabling Engineering Activity in Industry 5.0:

Engineering Simulation software developers have already taken note of how Industry 5.0 is shaping up and how it could help bring best of computing world and human participation. Simulation software developers having implemented Digital Twin, VR/AR, ROM’s and automation as part of Industry 4.0 enablers are now looking at engineering process automation in new dimension considering benefit of human intelligence as part of it.

Auto‘man’tion in Industry 5.0:

What can make a difference to practicing CAE users and Design teams in general is CAE / Virtual Validation process automation, which has human intelligence playing interactive role. This means it does not end with creating requirements and inputs but in walking through the process sharing the best of computing and human intelligence.

As technological innovations become ever more rapid, revolutions could ultimately follow one another in quick succession over the next 10 years and beyond. Whereas the first three industrial revolutions took decades to play out, today’s revolutions last only as long as it takes for industry-wide implementation to complete itself. With the innovative technologies continue to gain momentum in the industrial space, it’s natural that the relationship between man and machine will become increasingly interconnected.

Overall, the development of Industry 5.0 could prove to be the full realization of what the architects of Industry 4.0 had only dreamed of at the dawn of the 2010s. As artificial intelligence improves and factory robots assume more human-like capabilities, the interaction between computers, robots and human workers will ultimately become more meaningful and mutually enlightening.

DEP & Industry5.0:

DEP with the latest version of MeshWorks, is equipped to cater to the needs of Industry 5.0, as engineers manage customization / personalization in products being developed utilizing strength of collaborative process automation. Morphing, Parameterization tools and process automation methodology adopted in MeshWorks are not only delivering advantage to virtual validation users today but would stay relevant in the realm of Industry 5.0.

What is the media saying about DEP and Industry5.0?

Click Here to read our Collaborative Automation article

Click Here to read our Industry5.0 article

Watch Here Webinar of What Industry 5.0 framework means to product development and business