Multi-Disciplinary Optimization

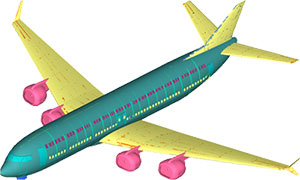

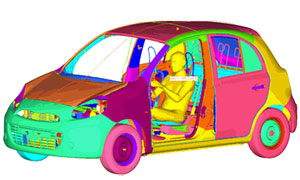

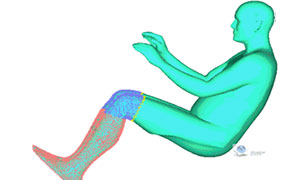

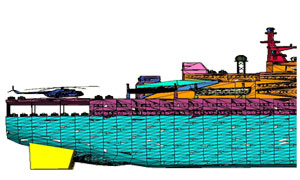

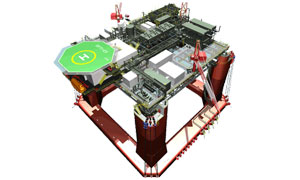

Multi-Disciplinary Optimization (MDO), also known as multidisciplinary system design as it is a branch of engineering which uses optimization to mitigate design problems with integration of many disciplines. It has a wide used in the engineering industry such as automobile design, computers, naval architecture, electronics and electricity distribution. But majorly multi-disciplinary optimization finds its purpose in aerospace and defence industry.

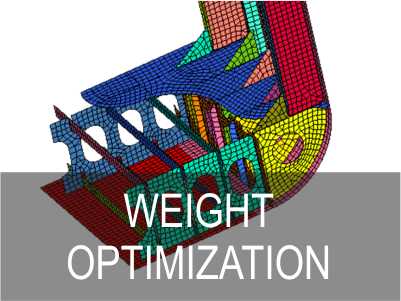

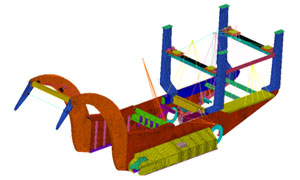

DEP (Detroit Engineered Products) has a strong background in providing engineering solutions and product design in the Aerospace and Defence, Automotive, Medical Devices, Construction equipment industries. But MDO has a wide application in design structures and aerodynamics. With the help of personalized computers and software tools there is a huge development in MDO, as many disciplines can be incorporated at a time to find the solution to the design problem. Some of the disciplines used widely in the multidisciplinary optimization process are Statistics and design of experiments, Multi-objective optimization, Metamodels and calibration and Process integration. DEP (Detroit Engineered Products) has a solid team of design engineers in India and USA to give the solutions for your design problems. The team is well versed with the disciplines and latest MDO techniques to find the solution to your design problem. For example, the latest algorithms and metamodel creation in the multi-disciplinary framework enable the design engineer to mitigate arduous and big design problems. The complex MDO framework will break these big problems into subsystem so that they are solved and analysed in parallel using different disciplines.

The DEP (Detroit Engineered Products) multi-disciplinary optimization is used by many engineering companies in India and USA, it has established a brand to itself in the Aerospace and Defence, Automotive, Medical Devices, Construction equipment domains. DEP (Detroit Engineered Products) MDO team will systematically formulate your problem using standard procedures which include defining the design variables, understanding the constraints, setting the objectives, using models to define constraints and objectives and finally using standard form to display these functions. DEP (Detroit Engineered Products) will give you the required results by setting the objectives which could be minimizing the weight or reducing the cost and increasing the profits. The company’s first priority has always been customer satisfaction and will continue to be the first priority.